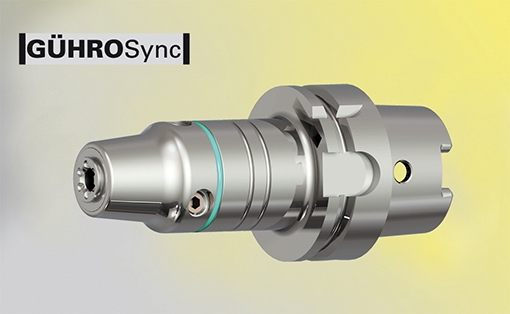

The synchro chuck offers all the advantages of hydraulic and synchro chucks in one system

The GühroSync synchro chuck ensures taps are under less strain as it is the only chuck that combines suspension with a long-life metal spring, damping with polymer spring elements and hydraulic clamping technology. This reduces the axial and radial forces when tapping and thread forming.

In order to improve upon the weaknesses of existing synchro chuck systems, Guhring developed the GühroSyncfrom a tool manufacturer’s perspective and incorporated decades of experience from the development, manufacture and application of threading tools in the new GühroSync synchro chuck. Practical applications show that the spindle dynamic and the axis drive of machines create synchronisation errors during the tapping process. During the initial tapping of the thread and when reversing the direction of rotation at the base of the thread there is the greatest deviation between the synchronisation of the rotation and feed axis. So the combination of synchro and hydraulic chuck provides GühroSync with the best of both systems:

- a considerable reduction of occurring forces

- simple and safe handling

- quick and accurate length setting of the tool

- torque transmission with positive drive

- torsion-damped driver

- modular design, various types, i.e. with shrink fit chuck are possible

Practical applications show that the spindle dynamic and the axis drive of machines create synchronisation errors during the tapping process. During the initial tapping of the thread and when reversing the direction of rotation at the base of the thread there is the greatest deviation between the synchronisation of the rotation and feed axis. Such synchronisation errors result in high forces acting on the tool. This in turn reduces tool life and leads to defective threads.

Force acting on rigid chuck

Based on this experience and the ever growing demand for longer tool life and shorter cycle times, it was clear that the existing chuck systems have to be improved or the quality and performance requirements cannot be achieved.

The aim was to equip the synchro chuck technology for current and future demands. A profile for the optimum synchro chuck was produced from the results of numerous tool trials. On the one hand the chuck should be easy to operate and on the other it should possess considerably improved clamping characteristics in order to achieve maximum transmission of torque. Very good damping characteristics, high concentricity and balancing quality rounded off the profile.

The solution was a combination of two excellent clamping technologies. GühroSync offers the advantages of synchro and hydraulic chucks in one system.

Thanks to the unique application of long-lasting metal spring and polymer damping elements the axial and radial forces are sprung as well as dampened. Loading at the thread flank is reduced so tool life and process reliability are considerably increased.

The usual collet chuck holder gives way to a considerably more comfortable to operate hydraulic chuck. Thus, the time and effort spent on clamping is reduced. Just one unique key is used for clamping, additional keys for locking or rings for sealing are not required. The positive drive of the tool by the hydraulic chuck optimally transmits the full torque.

Structure GühroSync

The smooth, edge-free design prevents contamination and swarf trapping during the machining process. The modular structure of the chuck enables various standard and special designs, i.e. longer or reduced diameter models. All variants can also be combined with Guhring’s MQL or GÜHROJET technology.