A proper tool management system can save tool costs and shorten NC programming and positioning times provided the actual, real tool data is available to CAM programmers during the programming stage.

It’s an ongoing challenge. To remain competitive, shops must find new and more efficient ways to increase production. Often they look to new, faster and more precise machine tools as the answer. Sometimes experimentation with a variety of different tooling solutions brings added savings in cycle times. To get the most out of the machines on the floor, a shop must keep them producing parts. When part runs are short, reducing machine downtime becomes even more vital, and tooling setups must be highly efficient. Naturally, having the tools management and ready for the next operation allows for faster change-over from one job to the next, keeping a machine’s idle time to a minimum. Offline tool presetting and tool management are sometimes viewed as an excessive and unnecessary cost, but without it, the operator depends on a far more expensive, yet often less accurate, Tool Management—the machine tool itself—to handle the tooling setup. As long as the machine is being used to touch off tools to establish initial tool offsets and to cut trial parts, it cannot be making money for the shop. This significant draw on spindle cutting time can make the difference in a shop’s profitability.

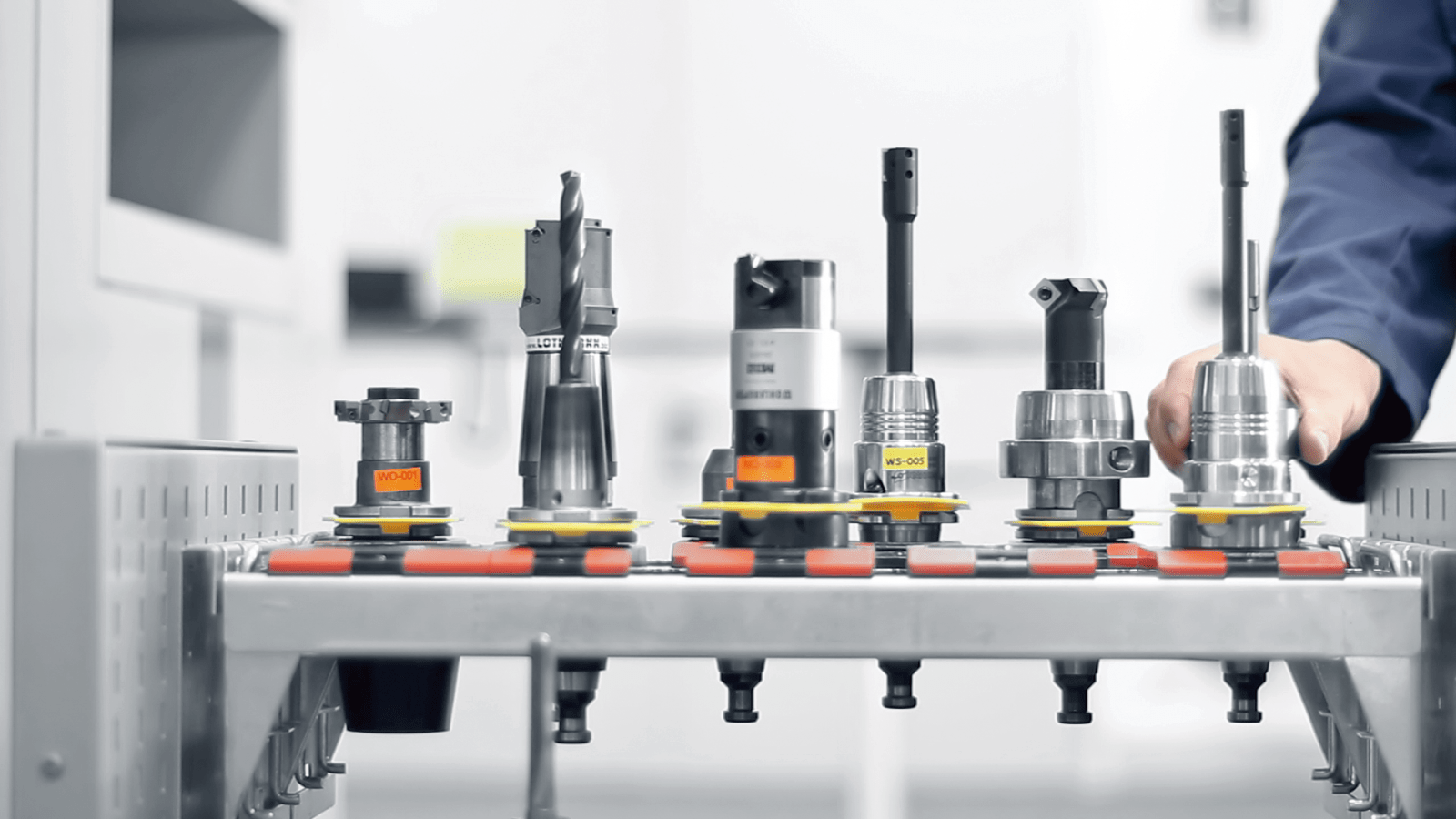

The ZOLLER solution for tool management organization

Zoller has designed a system to manage tools which covers all kinds of tool operation from Tool Presetter, Tool Inspection which works together with TMS (Tool Management Solution). These 3 elements are the essential part of the future factory. The database like z.One will be the center and the data can be managed according to the user requirements. The features include the management of Tool life, the connectivity of tools to work with all relevant departments in the factory in various stages from Planning, CAD/CAM design, Inventory, Tool setting and measuring, as well as Machine collaboration. Nowadays, the database has been set with centralized standard by the world’s manufacturers.

ZOLLER »flash« is software to indicate the Tool Life in machine to determine whether it is approaching the expiry date. When the tool is reaching its expiry date, the system will give 3 kinds of warning according to the color system (green, yellow, red) to the tool management system so that it knows beforehand. In every step of the tool management there will be an indication of whether the tool is the right size based on the Tool Presetter and then the data will be sent to the machine automatically. The operator can work on the machine on time and also without any damage or error.

ZOLLER »cetus« will manage tools required for the manufacturing process by converting all steps in the workflow into setup sheet. We can process and display all the tools we have in order to prepare the right tools for each moment and this will reduce the cost of tool management as well as the quantity of tools we store. Therefore, it is an efficient way of tool management.

ZOLLER Cost per Part (CPP) is a good example of how to manage the cost of the tools in an effective manner. When we collect the data regarding the tools from all the manufacturing processes, we can analyze the amount of tool use, abnormal uses and how they affected the cost per part, the duration as well as the suitable number of tools for the next order, and the number of sharpening required, etc. These data will be useful because they can help us further reduce the cost of manufacturing.

THE BEST SOLUTION OF TOOL MANAGEMENT, COMBING GUEHRING’S FLEXIBLE TOOL DISPENSING SYSTEMS

Accuracy , Safety and Reliability have absolute priority in all Manufacturing Industry , Tool Management with Tool Dispensing systems always ensure the correct tool are applied , Storage area are always perfectly allocated as well as tool cost always 100% visible and controlled.

The three tool dispensing systems TM 326, TM 426 and TM 526 offer flexible possibilities for made-to-measure tool storage. According to demand and size of company there is a choice between different levels of automation. Individual dispensing possibilities such as drawers or spiral systems can be chosen. Guhring’s tool dispensing system is entirely adapted to the individual requirements of the customer and his business. This way the customer can utilize the possibilities! Numerous satisfied customers also confirm this.

BUILT-IN INTELLIGENCE – GUEHRING’s GTMS TOOL MANAGEMENT SOFWARE

All Guhring tool dispensing systems are controlled by the user-friendly GTMS. It allows the simple, quick and intuitive operation via the integrated touch-screen or an external reading device. At the same time it documents all relevant movement data of stock levels, triggers ordering suggestions and enables evaluations to different criteria.

The comprehensive and detailed reporting provides the best possible transparency of your tool stock and tool consumption and in addition enables an accurate cost allocation. Furthermore, interfaces enable the connection to various product management systems as well as an on-line link to customers via automated ordering processes.

Advantages:

- no more tool selection errors

- no uncontrolled tool withdrawals

- diverse combination possibilities of the various modules

- perfect adaption of storage area to the stocked tools

- optimal utilization of the available space

- Complete Cost Control and transparency

- 100% availability