Today’s machining centers feature higher spindle speeds and feed rates, but if you want to push this capability to the limit, there are some tooling considerations that must be addressed.

Though high-speed machining, be it milling, is one of the hottest topics, there are many ways to define what it means. Some say it’s spindle speeds running over some specified minimum rpm. Others define it as high cutting speeds or feeds, or a combination of the two. Whatever the definition, obviously it’s not just a matter of tooling up CNCs with the right cutting tools, then ramping them up, otherwise we’d have nothing to talk about. There are many ways to mill a workpiece using special machining tool with many interesting technologies. This article will show 2 latest technologies for milling a hard-to-cut workpiece.

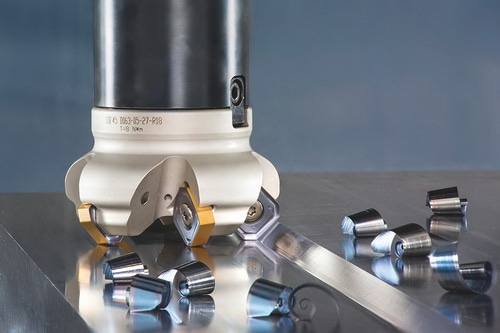

Iscar’s Helido 800 makes short work of steel and cast iron face milling

Iscar has expanded its popular Helido 800 line by introducing effective new face mills SOF45-R18 with 45° cutting edge angles. Intended for machining mainly steel and cast iron components at high metal removal rates, the new face mill family offers users an extremely cost-effective tool for productive milling across a range of cutting conditions.

The inserts are produced from the Sumo Tec carbide grades. They are secured in their pockets by angled screws that provide rigid and highly reliable clamping. The mills are available in a wide-diameter range 50 to 315mm. The advanced tool design that combines a strong insert structure, a durable cutter body, secure mounting and progressive Sumo Tec carbide grades, provides the customer with an innovative solution for 45° face milling operations.

SOF45-R18 milling cutter features

- Versatile face mills carrying inserts with eight cutting edges for up to 8mm D.O.C. or inserts with 16 cutting edges for 5mm D.O.C.

- Advanced cutting geometry that reduces cutting forces, and by extension power consumption, resulting in smooth cutting

- Well-secured inserts by means of angled screws

- Coarse and fine pitch configurations of the tools• Coolant holes (in up to 125mm cutters), directed to each cutting edge, for efficient cooling

- Highly economical solution regarding price per cutting edge

- Excellent performance under various machining conditions and interrupted cutting

- Productivity – high metal removal rates

PCD (Polycrystalline Diamond) Endmill

A hard solid and a very fragile material such as carbide whose hardness is over 90 HRC is usually used in an endmill in order to mill a less solid object whose hardness is not over 65 HRC. However, in the die-cutting industry or the molding process, carbide is often used as a mold which was unable to mill using a cutting machine. So, the forming process must be done using EDM (Electrical Discharge Machining) process which is time-consuming due to many processes involved.

However, with the latest technology from Japan, the world’s leading manufacturer of small endmill from Japan (NS Tool) has developed and invented Endmill to cut fragile and hard material with success. This is very beneficial for die cutting mold producers to cut carbide mold directly without EDM (Electrical Discharge Machining) process. With the technology of endmill PCDRB (PCD Ball End Mill) made of PCD (Polycrystalline Diamond) with special technique through a mixture of many chemicals resulting in PCD (Polycrystalline Diamond) which can be used to cut solid and fragile workpiece with effectiveness.

PCD (Polycrystalline Diamond) Endmill can be used to cut a workpiece to achieve a mirror surface up to a nanometer level with the following features:

Thanks to the properties of Back Taper, there is no problem with the chattering at the corner because the touch surface during the milling process is reduced, resulting in no chattering.

It is worth the investment and it is cost-effective. The used tools can be sent back to the manufacturers to be reformed for reuse for many times.

The test results of the surface roughness in each area at the nanometer level are shown above.

References:

www.iscarthailand.com

www.factorymax.co.th