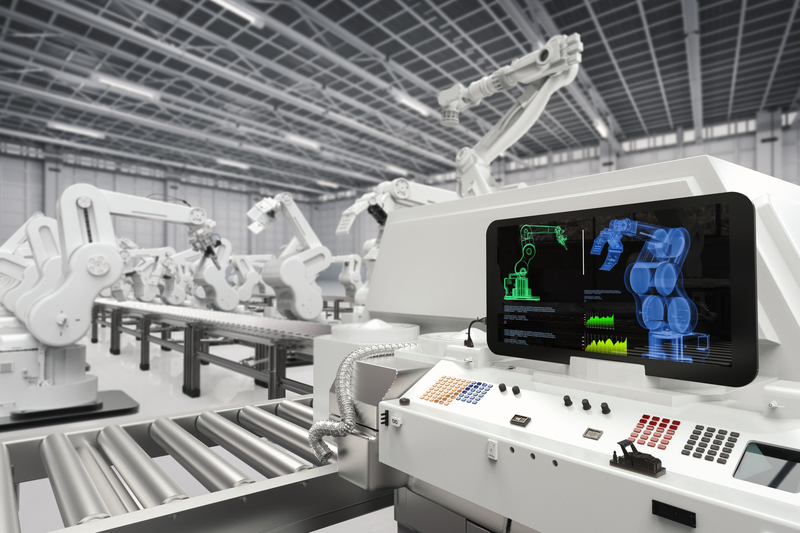

เมื่อผสาน AI และ Robotics เข้าด้วยกัน ก่อเกิดเป็นเทคโนโลยีหลากหลายความสามารถ ซึ่งนำไปใช้เพื่อขับเคลื่อนและเพิ่มประสิทธิภาพด้านต้นทุนในปัจจุบัน เทคโนโลยี AI เสริมความสามารถให้แก่อุปกรณ์เครื่องจักร ให้ประมวลผลเช่น เรียกข้อมูล รวบรวมข้อมูล ทำความเข้าใจรูปแบบของข้อมูล เรียนรู้และปรับอุปกรณ์เครื่องจักรให้ทำงานรับมือกับสถานการณ์ที่ไม่คาดคิดและไม่เคยเรียนรู้มาก่อน จากการวิเคราะห์ของ PwC พบว่า GDP ของโลกจะเพิ่มขึ้น 14% ในปี 2030 (เปอร์เซ็นต์ที่เพิ่มขึ้นนี้มีมูลค่าเท่ากับ 15.7 ล้านล้าน เหรียญสหรัฐ) ที่เป็นเช่นนี้เพราะมีการเร่งพัฒนารับเอา AI ไปประยุกต์ใช้นั่นเอง

Source: Robotics Outlook 2030: How Intelligence and Mobility Will Shape the Future, Boston Consulting Group

Source: The Future of Artificial Intelligence in Manufacturing Industries, Plant Automation Technology

ตามรายงานของสหพันธ์หุ่นยนต์นานาชาติ (IRF) สต็อกของหุ่นยนต์อุตสาหกรรมเพิ่มขึ้นเป็นจำนวน 3 เท่าในช่วงทศวรรษที่ผ่านมา ในปี 2020 พบว่ามีหุ่นยนต์มากกว่า 3 ล้านตัวนำไปใช้งานในหลากหมายอุตสาหกรรมเป็นที่เรียบร้อยแล้ว ภูมิภาคเอเชียเป็นผู้นำการเปลี่ยนผ่านไปสู่การใช้งานระบบกระบวนการอัตโนมัติ โดยมีการติดตั้งหุ่นใช้งานหุ่นยนต์อุตสาหกรรมอย่างบ้าคลั่งในประเทศจีน ซึ่งในปี 2020 จีนได้ติดตั้งหุ่นยนต์อุตสาหกรรมเป็นจำนวนถึง 168,400 ตัว คิดเป็น 44% ของตัวเลขการติดตั้งของทั่วทั้งโลก ซึ่งเป็นจำนวนที่สูงที่สุดเท่าที่เคยมีบันทึกไว้ (สำหรับประเทศเดียว) บริษัทต่าง ๆ เองก็กำลังลงทุนเพื่อสร้างหรือขยายโรงงานไปยังตลาดที่ทำเงินในต่างประเทศ สร้างประโยชน์จากโรงงานเหล่านี้ให้ได้มากที่สุด

Source: World Robotics 2021

Source: International Federations of Robotics, World Robotics 2021

ผลสำรวจล่าสุดของ PwC เปิดเผยว่าบริษัทผู้ผลิตระดับโลกมีแนวโนวที่จะโยกย้ายทรัพย์สินการลงทุนถึง 77% เพื่อสร้างโรงงานดิจิทัลในเยอรมนีและประเทศในกลุ่มยุโรปตะวันตกในอีก 5 ปีข้างหน้า ส่วนภูมิภาคอื่นเหมือนจะยังไม่ใช่ตัวเลือกที่น่าสนใจมากนัก ดูได้จากบริษัทผู้ผลิตรายใหญ่เหล่านี้มีแผนจัดสรรการการลงทุนดังกล่าวในภูมิภาคเอเชียเป็นจำนวน 7% และให้กับประเทศในภูมิภาคยุโรปตะวันออกเพียง 5%

Source: Digital Factories 2020: Shaping the future of manufacturing, PricewaterhouseCoopers

ที่มากไปกว่านี้คือการเปลี่ยนแปลงอย่างรวดเร็วนี้แนวโน้มส่งผลกระทบต่อลักษณะงานการผลิต เกิดบทบาทและงานใหม่ และเปลี่ยนแปลงงานเดิม อย่างไรก็ตาม การมุ่งมั่นทักษะดิจิทัลอย่างเข้มข้นจนมากล้น ไม่ได้แก้ปัญหาช่องว่างด้านแรงงานอุตสาหกรรมการผลิตในภาพรวม ไม่ได้เสริมสร้างศักยภาพให้แก่อุตสาหกรรมเพื่อรับมือกับ disruption ที่กำลังเกิดขึ้นแต่อย่างใด ทว่าความสามารถของมนุษย์โดยกำเนิด เช่น ความสามารถในการคิดเชิงนามธรรม ความสามารถในการตัดสินใจ ความสามารถทางสังคมที่มีความยืดหยุ่น รวมถึงพลังที่เกิดจากการสร้างบันดาลใจ จะเป็นชี้ว่าพนักงานฝ่ายผลิตในวันพรุ่งนี้ว่าจะไปต่อกับยุคดิจิทัลและขับเคลื่อนผลลัพธ์หรือไม่

Source: Sizing the prize, PricewaterhouseCoopers

แนวทางที่มีความเป็นไปได้ในทางปฏิบัติมากที่สุดที่บริษัทในกลุ่มอุตสาหกรรมการผลิตจะใช้เพื่อรับมือวิกฤตจากการเปลี่ยนแปลงที่กำลังเกิดขึ้นนี้ คือการปรับทักษะและยกระดับทักษะให้กับพนักงาน แต่ก่อนที่บริษัทจะสามารถเพิ่มทักษะและเพิ่มทักษะให้กับพนักงานได้ บริษัทต้องรู้ก่อนว่าทักษะใดเป็นทักษะเฉพาะในองค์กร ทักษะใดจำเป็นสำหรับงานใหม่ และทักษะใดจำเป็นการก้าวข้ามไปสู่อนาคต จากที่กล่าวมานี้ จึงทำให้กลยุทธ์การบริหาร บุคลากรแบบ end-to-end จะเป็นปัจจัยทรงอิทธิพล ที่สามารถบ่งชี้ความสำเร็จหรือความล้มเหลวของการปรับและยกระดับทักษะบุคลากร

Source: Creating Pathways for tomorrow’s workforce today, Deloitte Insights

นอกจากนี้ การปรับและยกระดับทักษะความสามารถให้แก่บุคลากรถภายใน ยังช่วยให้องค์กรมีข้อได้เปรียบหลายประการ เช่น ช่วยลดระยะเวลาการบรรจุตำแหน่งงาน พนักงานรู้สึกว่าได้รับการเอาใจใส่มากขึ้น บริษัทและการดำเนินงานลื่นไหลมีประสิทธิภาพมากขึ้น เกิดประสิทธิภาพด้านต้นทุน ผลการศึกษาสำรวจทิศทางและแนวโน้มแรงงานโลกของบริษัท LinkedIn ได้ค้นพบว่า องค์กรเห็นพ้องว่าการพัฒนาทักษะซึ่งต่อโจทย์การสรรหาภายในทำให้พนักงานไม่คิดลาออกถึง 81% และ องค์กรเห็นพ้องว่าการพัฒนาทักษะเกิดผลพวงเป็นการเร่งกระบวนการจ้างพนักงานเพื่อบรรจุตำแหน่งงานมีประสิทธิภาพถึง 69% เมื่อได้ทราบคุณประโยชน์จากข้อเท็จจริงนี้แล้ว บริษัทผู้ผลิตไม่ควรรอช้าและดำเนินการได้ทันที

Source: Creating pathways for tomorrow’s workforce today, Deloitte Insights

Article by: Asst. Prof. Suwan Juntiwasarakij, Ph.D., Senior Editor and MEGA Tech