With the rapid development of electric and electronic technology, information technology and advanced manufacturing technology, the production mode of manufacturing enterprises is being transferred from digital to intelligent. The new era that combines Virtual Reality Technology based on the Cyber-Physical System (CPS) is coming. Due to the new challenges, the advantages of traditional manufacturing industries have been gradually diminished. Consequently, the intelligent manufacturing technology is one of high technology areas where industrialized countries highly pay more attention to. Europe 2020 strategy, Industry 4.0 strategy and China manufacturing 2025 have been proposed. United States has gradually accelerated the speed of reindustrialization and manufacturing reflow. The transformation of intelligent manufacturing intrigued the profound and lasting effect on the future manufacturing worldwide.

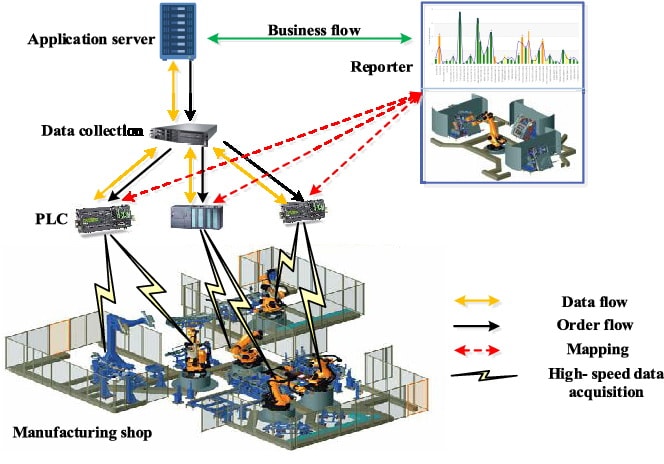

In the implementation of smart factory, the IIoT(Industrial Internet of Things) is employed to integrate the underlying equipment resources. Accordingly, the manufacturing system has abilities of perception, interconnection and data integration. The data analysis and scientific decision are used to achieve production scheduling, equipment service and quality control of products in smart factory. Further, the Internet of services is introduced to virtualize the manufacturing resources from a local database to the cloud server. Through the human-machine interaction, the global collaborative process of intelligent manufacturing oriented to the order-driven market is built. Therefore, the smart factory represents an engineering system that mainly consists of three aspects: interconnection, collaboration and execution. As shown in Fig. 1, the architecture of smart factory includes four layers, namely physical resource layer, network layer, data application layer, and terminal layer. With the aim to convert modern factory into smart factory, key technologies involved in all layers have to be studied in detail.

Therefore, it is very important to enhance the intelligence of robots units. Several suggestions for construction of modular manufacturing units are proposed as follows:

- Modular manufacturing units should cooperate with each other to accomplish the common tasks, where the emphasis is on the mutual perception and the collaboration mechanism between intelligent modules. In addition, heterogeneity of interaction should be took account.

- The functions of different modular manufacturing units may be redundant for a certain product, therefore it is crucial to make an optimal or suboptimal combinatorial scheme.

- Each manufacturing unit can not only meet the manufacturing requirements of products, but also improve the smart factory efficiency in a self-organized way.

Various kinds of special sensors are used to collect data in manufacturing area, wherein devices are independent of each other. The collected data are heterogeneous with uneven quality. Therefore, the communication interface of intelligent equipment should be compatible with a series of communication protocols. For instance, it should be compatible with OPC, Open Database Connectivity (ODBC), RS232, Dynamic data exchange (DDE), etc., which are used to connect control systems such as Supervisory Control and Data Acquisition (SCADA), Distributed Control System (DCS), and Process Control System (PCS). In addition, data acquisition devices should be easily set up and their interfaces should be flexible and scalable. The manufacturing resources should support a fine-grained data acquisition in process visibility system. As show in Fig. 2, the equipment operating state is similar to the human heart beating. The equipment health management system, which is based on the monitoring equipment status obtained by the “electrocardiograph (EGC)”, can predict system failure and arrange necessary maintenance activity in advance. However, current pattern of data acquisition is still a bottleneck of intelligent manufacturing that will continue to evolve.

General, an information model is built in the control system to perceive operation condition, while reasoning decision is made according to the information of evaluation module. Moreover, the controller system completes reconfiguration planning and implements processes automatically for specific needs of support for interoperable technology, such as interactive interface, results in high flexibility. The reconfigurable production line can generate a large range of different products due to its variability, scalability and schedulability, which is the basis of flexible manufacturing in smart factory. Presently, the problem of production line is strong specialty, which can be enhanced by advance planning and control methods to build a reconfigurable system to simulate the production line and propose a scheme for reconfiguration. The feasibility of proposed scheme is verified by the manufacturing scenario. With the aim to respond timely to the market requirements, it is necessary to implement a reconfigurable production line in the smart factory.