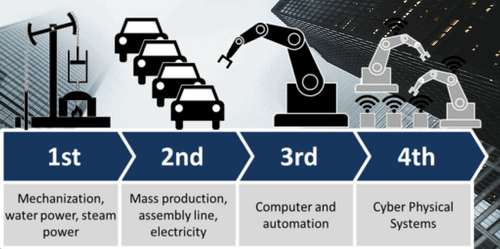

In many industrial sectors, there have been attempts to move forwards and develop a new way of development to reach Industry 4.0. Besides automation system, other technologies to plan the management system through fast communications are at the heart of manufacturing process to operate effectively.

Management in each manufacturing process is interrelated, especially in the form of chain which begins at the beginning until the end of cycle. In each cycle, there must be a manufacturing system to increase the maximum effectiveness, from product development, manufacturing plan, and the logistics system between suppliers and customers. Many leading manufacturers have tried to increase the competitiveness in order to meet the demands of the market through the increase of manufacturing efficiency instead of machinery investment because the increase of manufacturing capability requires a high amount of investment and takes a long time to recover the investment. Through technology in manufacturing cycle, it is a good method to increase the convenience in management. There are many technologies for different kinds of works.

Enterprise Resource Planning (ERP)

ERP is a tool used in business management to resolve problems inside the organization and to help plan the budget and the overall resource management of the organization an in effective manner. It also goes beyond the boundaries among departments, making a holistic management possible so that the organization reaches the best benefit. It is an approach which brings in business process alongside applications in each department to become an enterprise with data stored at one place for simple usage. This system is still limited in terms of manufacturing because it can only store overall manufacturing data. It does not involve the management of manufacturing process and the design which means that some factories need to use other kinds of software to complement the overall manufacturing efficiency.

Manufacturing Execution System (MES)

Because ERP system is still limited in many aspects, some processing data cannot be accessed. MES is designed to cover more processes inside the factory during the suitable time. It covers 3 major process as in PRODUCTION, PERSONNEL and QUALITY. It begins with the order from the customers, the manufacturing plan, and the plan to receive raw materials and workpieces from suppliers to the manufacturing process for higher effectiveness and the highest possible quality yet with a low cost. Therefore, MES plays a central role in exchanging data with ERP system and the job on the site in order to make the data more real-time. Besides, MES can be used as a monitor to track what is happening on the site in order to make an immediate decision when necessary. This machine can also transfer and display data directly without any other staff member or other medium.

Product Lifecycle Management (PLM)

PLM is a system to manage the product lifecycle with the aim to collect all organizations into the product lifecycle management from the idea stage to the design in CAD/CAM/CAE in order to develop the product as well as predictive engineering analytics and mechatronic system simulation (1D CAE) which is used to design the production in the optimal condition before the actual development. Finite element analysis (FEA) is used to analyze the manufacturing process with high complexity. Modal testing and analysis is used for planning the manufacturing process and the energy usage for the optimal output and the use of products, including the whole processing system to increase the efficiency in the world’s competitive market. At the present moment, PLM can also be used as a Product Data Management platform which collects information about the personnel, the processes, the business administration system, and the security system alongside data as the main system for a large organization. Currently, it is the most popular system.

Manufacturing Operations Management (MOM)

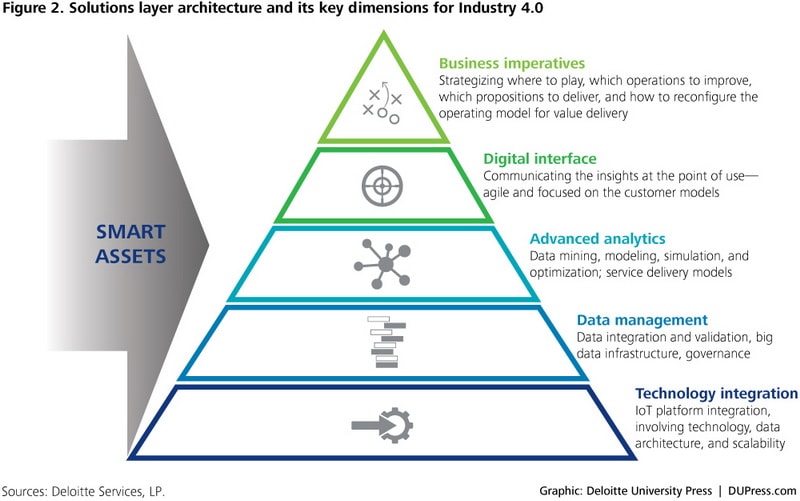

MOM is a novel approach which becomes highly successful. It has been widely used in industrial sectors in Europe and America. This approach combines PLM and MEs with SCADA Intelligence system and Manufacturing Intelligence to control a wide range of processes from research and product development, the increase of flexibility to the manufacturing method according to the customer’s demands, advanced planning and scheduling, the manufacturing process from the starting point to the final product with the most suitable output so that the overall manufacturing efficiency is the best. It uses software and automation system to control the whole system in a real-time manner from the production management, the analysis of production efficiency, the quality control as well as the quality assurance including human machine interface (HMI), to name a few. It can be said that this system can be used to embrace the concept of Industry 4.0.