Medical applications for 3D printing are expanding rapidly and are expected to revolutionize health care. Medical uses for 3D printing, both actual and potential, can be organized into several broad categories, including: tissue and organ fabrication; creation of customized prosthetics, implants, and anatomical models; and pharmaceutical research regarding drug dosage forms, delivery, and discovery. The application of 3D printing in medicine can provide many benefits, including: the customization and personalization of medical products, drugs, and equipment; cost-effectiveness; increased productivity; the democratization of design and manufacturing; and enhanced collaboration. However, it should be cautioned that despite recent significant and exciting medical advances involving 3D printing, notable scientific and regulatory challenges remain and the most transformative applications for this technology will need time to evolve.

Common Types of 3D Printers

All 3D printing processes offer advantages and disadvantages. The type of 3D printer chosen for an application often depends on the materials to be used and how the layers in the finished product are bonded. The three most commonly used 3D printer technologies in medical applications are: selective laser sintering (SLS), thermal inkjet (TIJ) printing, and fused deposition modeling (FDM). A brief discussion of each of these technologies follows.

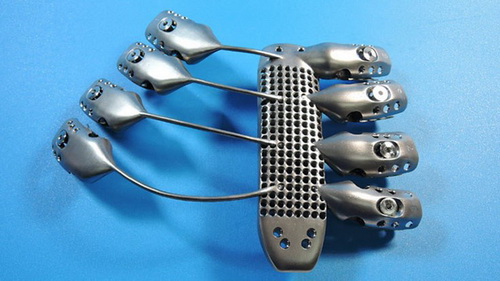

Selective Laser Sintering

An SLS printer uses powdered material as the substrate for printing new objects.1 A laser draws the shape of the object in the powder, fusing it together. Then a new layer of powder is laid down and the process repeats, building each layer, one by Medical Applications for 3D Printing: Current and Projected Uses one, to form the object. Laser sintering can be used to create metal, plastic, and ceramic objects. The degree of detail is limited only by the precision of the laser and the fineness of the powder, so it is possible to create especially detailed and delicate structures with this type of printer.

Thermal Inkjet Printing

Inkjet printing is a “noncontact” technique that uses thermal, electromagnetic, or piezoelectric technology to deposit tiny droplets of “ink” (actual ink or other materials) onto a substrate according to digital instructions.2 In inkjet printing, droplet deposition is usually done by using heat or mechanical compression to eject the ink drops. In TIJ printers, heating the printhead creates small air bubbles that collapse, creating pressure pulses that eject ink drops from nozzles in volumes as small as 10 to 150 picoliters. Droplet size can be varied by adjusting the applied temperature gradient, pulse frequency, and ink viscosity.

TIJ printers are particularly promising for use in tissue engineering and regenerative medicine. Because of their digital precision, control, versatility, and benign effect on mammalian cells, this technology is already being applied to print simple 2D and 3D tissues and organs (also known as bioprinting). TIJ printers may also prove ideal for other sophisticated uses, such as drug delivery and gene transfection during tissue construction.

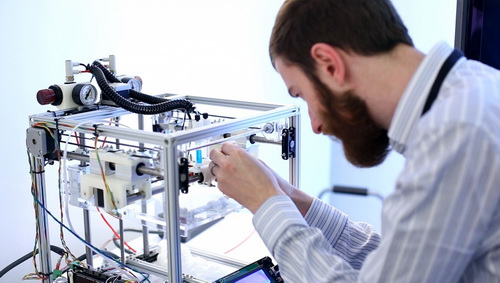

Fused Deposition Modeling

FDM printers are much more common and inexpensive than the SLS type.1 An FDM printer uses a printhead similar to an inkjet printer. However, instead of ink, beads of heated plastic are released from the printhead as it moves, building the object in thin layers. This process is repeated over and over, allowing precise control of the amount and location of each deposit to shape each layer. Since the material is heated as it is extruded, it fuses or bonds to the layers below. As each layer of plastic cools, it hardens, gradually creating the solid object as the layers build. Depending on the complexity and cost of an FDM printer, it may have enhanced features such as multiple printheads. FDM printers can use a variety of plastics. In fact, 3D FDM printed parts are often made from the same thermoplastics that are used in traditional injection molding or machining, so they have similar stability, durability, and mechanical properties.

Benefits of 3D Printing in Medical Applications

The greatest advantage that 3D printers provide in medical applications is the freedom to produce custom-made medical products and equipment. For example, the use of 3D printing to customize prosthetics and implants can provide great value for both patients and physicians. In addition, 3D printing can produce made-to-order jigs and fixtures for use in operating rooms. Custom-made implants, fixtures, and surgical tools can have a positive impact in terms of the time required for surgery, patient recovery time, and the success of the surgery or implant. It is also anticipated that 3D printing technologies will eventually allow drug dosage forms, release profiles, and dispensing to be customized for each patient.

3D printing has become a useful and potentially transformative tool in a number of different fields, including medicine. As printer performance, resolution, and available materials have increased, so have the applications. Researchers continue to improve existing medical applications that use 3D printing technology and to explore new ones. The medical advances that have been made using 3D printing are already significant and exciting, but some of the more revolutionary applications, such as organ printing, will need time to evolve.