Metal 3D printing is one of the technologies which have been around for a long time but have not been well-received in Thailand’s markets due to a few limitations such as the high price (over 10 million per unit), an extremely slow manufacturing process, laser device safety and dangers associated with metal powder.

Thaisakol Group in collaboration with Desktop Metal introduces Metal 3D printing technology to revolutionize the manufacturing process for metal parts in Thailand. Desktop Metal could offer a metal 3D printer with a 10x lower price than the market but with 100x more efficiency. Desktop metal has developed 2 lines of 3D printer to cover all manufacturing processes from prototyping to mass production. Each workpiece meets the high quality standards with the low cost of manufacturing, the high speed of manufacturing and the safety during operation.

Let’s begin with Studio System™, a Metal 3D printer designed for the prototyping or low volume production purposes or for replacement and spare parts. Moreover, the cost is 10 times cheaper than the traditional metal 3D Laser-based printing technology. Studio System also works on a cloud so that engineers can choose digital files for direct printing without accessories or software because the only requirement is the ability to be connected to the internet.

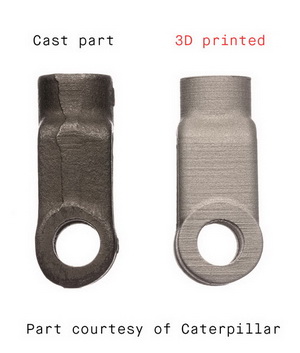

Studio System uses a printing technique called BMD (Bound Metal Deposition™) which is similar to FDM system, that is, the melting and the injecting of metal materials layer by layer. The material used is a metal rod which is safe to use (the texture of the material is mixed with metal power and polymer binder). This is different from laser-based technology which uses laser to melt metal powder.

After the completion of printing, the workpiece will be put into a Debinder which dissolves any binder within the workpiece by a special chemical agent created by Desktop Metal. Moreover, the Debinder prepares the workpiece before placing it in a furnace which will burn and drive out the remaining binder until the metal workpiece achieves the density of between 96-99%.

For the manufacturing industry specialized in the mass market, it is important to have an assistant like Production System™, a metal 3D printer which is designed for mass production with 100 times faster speed than the current Metal 3D Laser-based printing technology thanks to the Single Pass Jetting (SPJ) technique which can print to and fro between two directions with the speed of 8200 cm³ per hour. The printing press will spray metal powder and print alternatively on the workpiece. It can spray over million drops per second.

Besides, the workpiece created through Production system contains fine metal powder in each layer and therefore a large number of workpieces can be manufactured at a time with software to organize the manufacturing area so that the maximum number of workpieces can be made, resulting in 20 times lower cost per piece.