Although the measurement technology which uses CMM Arm alongside Laser Scan has been in use for over 10 years and played a significant role in the industrial sectors of Thailand, this CMM Arm + Laser Scan technology is still popular. The Vectoron System model by TBTS has been continuously developed so that the system is more effective and meets the requirements of the modern day users.

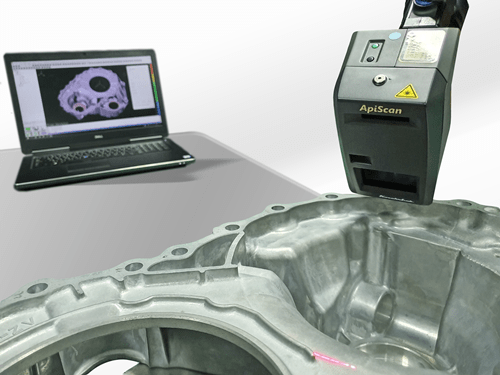

New Vectoron VMC-7000M system is the latest Portable CMM + Laser scanner from Japan. It can be applied in various areas such as product inspection and reverse engineering.

The features which make this model different from other previous models are as follows: The measuring arm has an electronic break to lock the movement of the arm at the fifth axis, allowing users to work more conveniently and completely safe. It can run on battery and can transfer data to computers through WiFi.

Moreover, users can choose the type of scanner head to fit the type of work, such as Line Scanner (Raptor Eye2) which has speed of 400 Hz and ability to store data at 640,000 Point/Sec. With this scanner, users can scan a workpiece of 1 square meter in size within a few seconds.

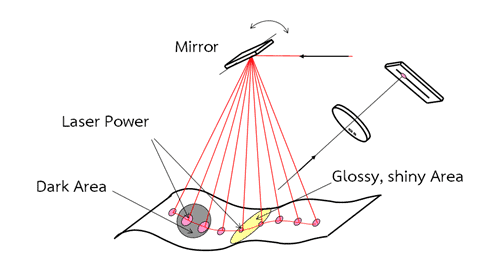

If users would like to achieve high quality data or work with a complex workpiece, users can use Flying Dot scanner (API Scanner) with various modes to choose from in order to meet different requirements. The scanner can work with the maximum frequency of 100Hz with ability to store data at 150,000 Point/Sec. It can store the details of the data at 0.015mm. Therefore, it can be said APiScan is the fastest Flying Dot scanner of the current era without any need to spray on the workpiece.

The length and the details of the scanning line can be adjusted to meet 5 types of work such as a non-complex workpiece which requires speed or a workpiece which requires fine details at the edge. With various modes of operation, users can scan complex locations and gain high quality data so that users can apply them to various types of work in an effective manner.