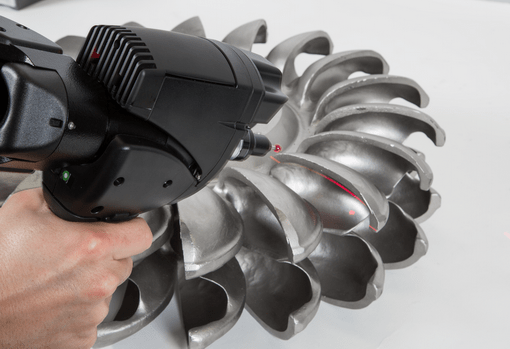

Every day, engineers and quality managers encounter increasingly demanding applications while up against the need to constantly increase the efficiency of their assurance processes. Facing these challenges of modern production was what drove the development of the new RS4 laser scanner, which comes packaged with the ROMER Absolute Arm with Integrated Scanner.

With the RS4 laser scanner, almost any part, of almost any material, can be fully digitised in three dimensions in almost no time at all. The scanner’s high data resolution and quality have been clear to customers facing these challenges from the day it first went on sale, especially when it comes to evaluating mixed production materials and varied surface finishes.

Users in automotive manufacturing will be familiar with issues such as these – the fast and efficient evaluation of mixed finishes and materials within a single product are a challenge they come across on a regular basis. This can be seen in the popularity of combining smooth and shiny surfaces in modern car interiors with the “soft-touch plastics” mentioned in every relatively high-end car review. Shiny or matte, smooth or deeply textured, rich black or multi-coloured, from plastic to carbon-fibre to brushed aluminium – the range of materials put to work in contemporary car interior design is extensive, often even within the same model.

Such variation is very difficult from a production standpoint, and is just as challenging to deal with when the goal is to comprehensively control for quality and defects. While consumers love the finishes, it can be a real production bottleneck – it doesn’t matter how quickly cars are being assembled if the speed of the quality team is limited by slow assessment tools. Rising to this sort of challenge was firmly in mind when the newest ROMER Absolute Arm SI was still on the drawing board.

Meeting this need for evaluating multi-material, multi-finish and multi-colour products without any need for surface preparation such as spraying has been a key feature of the ROMER Absolute Arm SI since its launch. Users can just put the arm into position, turn on and start scanning – no warm-up, no-calibration, just high-quality modelling data right out of the box. It’s a scanner that’s perfectly at home on almost any surface.

So retaining this market-leading multi-surface scanning capability while accelerating the measurement process speed is what was vital during the development of the RS4 laser scanner. The result is the introduction of a much wider laser line – up to 150 millimetres – that can collect up to a massive 752,000 interpolated data points every second. The difference in speed that delivers is big –the RS4 can scan the same part in only 60 percent of the time previously needed. That’s a number that speaks for itself, and what it says is “huge production efficiency improvement”.

And that’s what the RS4 is all about – the same portability, versatility and accuracy that the ROMER Absolute Arm with Integrated Scanner is known for, only even better, faster and easier to use. At Hexagon Manufacturing Intelligence they call that quality driving productivity.