With the automotive industry’s continuing push to reduce inspection cycle times, traditional tactile probe and data-gathering technology is often too slow to support most full-body and body-assembly inspection requirements for timely process-control applications. Consequently, automakers and coordinate measuring machine manufacturers are continually evaluating improved methods for gathering and analyzing dimensional data.

One new approach focuses on high-speed scanning using CMMs that automatically measure the shape and form of workpieces. The CMMs then incorporate the information with CAD systems to provide insight into the manufacturing operation. High-speed scanning is simply a way of automatically collecting a large number of data points to define a part’s shape quickly and accurately. Such noncontact gaging-when used for subassembly and body-in-white inspection applications–offers accurate real-time monitoring of quality output from the production line as well as the flexibility to handle line changes.

For several years, CMMs have been used as in-line measurement and inspection systems for body-in-white applications. In many of these cases, however, CMMs are equipped with tactile analog probes to gather dimensional data. These probes are durable, heavy-duty electronic sensors that provide a high degree of data accuracy, albeit at a relatively slow speed.

The significant difference between optical measurement and touch-probe measurement is that the touch-probe method finds the edges of parts by calculating the intersection of planes and other features based on a few points. Optics can find the edges directly. Touch-probe systems are limited in their analysis by the amount of points that they gather. Further, each point eats away at precious measurement cycle time because each measurement requires that the probe approach, contact, withdraw, and reposition. Optics can gather hundreds of points with each snapshot. Any feature that can be measured optically can be measured faster and more accurately due to the amount of information quickly gathered. Programming time for machine positioning is also shortened.

Putting noncontact sensors to work

Although noncontact sensors are used in a variety of measurement and inspection applications, applying their technology to the 3-D dimensional control of car bodies on the production line has been challenging. The first relatively successful application of the technology was with a stationary multisensor inspection cell that uses a number of CCD camera/laser light sensors to gather dimensional data. The system meets production cycle-time requirements by simultaneously measuring a number of body elements, determined by the number of sensors installed in the cell.

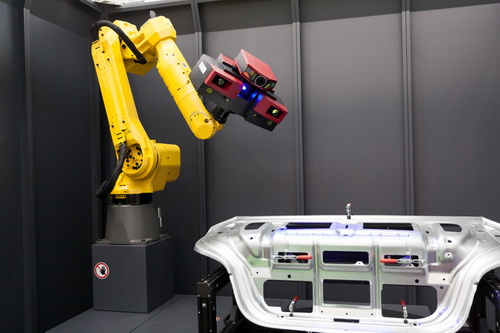

The stationary multisensor approach has some limitations. Due to the large number of sensors required in each cell, it’s expensive to manufacture, and maintenance is often complex and costly. The system generates relative, rather than absolute, measurement data and requires gold masters that must be certified and carefully stored to support the periodic certification of cell performance. In addition, the system can’t be easily reconfigured to meet varying production-line applications However, the solution in combining CMM flexibility with noncontact sensor data-gathering technology. CMMs used for body-in-white inspections are called “measuring robots.” These are generally designed as horizontal arms, the only structure capable of reliable dynamics, high accuracy and the long measuring strokes needed for full car-body inspection. The design is also well-suited for adding a second arm to create a multi-axis inspection cell. With such a configuration, cycle time is dramatically reduced, throughout is maximized and measuring errors are minimized.

Measuring robots with optical sensor are fast, accurate and rugged machines designed to operate in the most severe production environments. They can be easily integrated, in-line or side-by-side, with production equipment. They also resist ambient shop-floor conditions such as temperature gradients, airborne contaminants and vibrations. Internal positive air-pressure systems keep critical components clean. Machines are constructed from materials that ensure an optimal rigidity-to-weight ratio and react well to thermal variations.