For larger workpieces where sheer size creates an accessibility problem, horizontal arm coordinate measuring machines (CMMs) remain a staple for manufacturers requiring accurate dimensional data. Mr. Kacha Panyaroj, Sales Manager – CMM & Vision at Hexagon Manufacturing Intelligence, explains why this technology is the go-to for many industries.

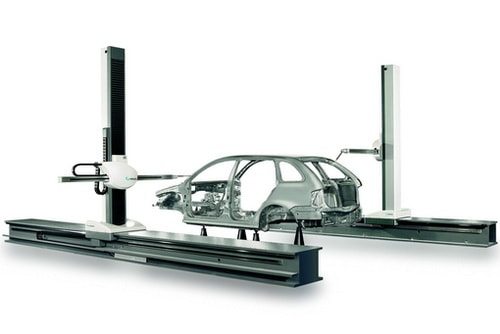

Horizontal arm coordinate measurement machines (CMMs) are most traditionally associated with use in the field of automotive body-in-white. However, the numerous unique advantages of such systems mean they are widely used across a variety of sectors where other measurement solutions struggle to compete. Like bridge and gantry CMMs, horizontal arm CMMs provide accurate and relevant data both in the control room and on the assembly line. So what makes this class of machine different and what applications are they suited to?

Typically, the key differentiator is the size of the workpieces being measured. The ability to measure large parts on a bridge CMM is limited by the size of the measurement volume, and the structure of the machine itself can also cause accessibility issues. In contrast, the ease of access that horizontal arm machines provide makes them ideal for measuring very long or tall workpieces. Often, manufacturers find that a horizontal arm CMM offers better cost to volume ratio than a bridge CMM capable of accommodating the same size parts. They also have a significantly smaller footprint and require less ceiling height than a bridge CMM with the equivalent working volume.

The advantages of horizontal arm CMMs are particularly apparent when inspecting sheet metal parts in the car industry, but manufacturers of other large-sized components such as those found in the aerospace, shipbuilding, defence, appliance, machinery and railway industries also benefit from these highly-adaptable machines.

Unlike some gantry-type CMMs, horizontal arm machines with an integral plate do not require specialist foundation systems. This makes installation quicker and less expensive, while it is also comparatively easy to relocate a horizontal arm system. In the automotive industry, horizontal arm CMMs are installed in a number of departments to meet the different dimensional data requirements throughout the product lifecycle.

Horizontal arm CMMs are frequently used to optimise the process, increase data production and reduce the measurement time required in the prototype construction and dimensional validation phases of vehicle development. Many manufacturers are today increasing their data requirements during prototyping, with considerable quantities of very accurate data now offering the potential to improve time to market, a key priority for this competitive industry.

Horizontal arm CMMs can also be integrated as a component within an automated production line such as an automotive body-in-white setup. Their robust mechanical frame is suitable for shop-floor operations, while the open structure permits direct access to the workpiece and significantly improves the ease of loading and unloading.

In performance terms, horizontal arm CMMs can make a direct contribution to reducing measuring cycle times. This is essential to keeping the production process under control in real time. Horizontal arm CMMs can be equipped with fixed or indexable measurement heads and continuous wrists that allow fast and accurate measurement, even in hard-to-reach places such as underneath a car chassis and inside an assembled car body. The two arms can be equipped with touch-trigger probes as well as optical sensors. The option for tactile and optical scanning makes the inspection process within the production line quicker and more efficient.

Horizontal arm CMMs are extremely modular and easy to configure, combining the flexibility and programmability of a CMM with the speed and intuitive use of traditional measuring gauges. The flexibility of the machines allows the inspection of several components within a single measurement cell. Horizontal arm CMMs also offer several configuration types to suit a range of factory setups. Some have integrated worktables, while others use a remote worktable or a movable fixture. Dual-arm configurations are also available, doubling the inspection area and potential inspection speed.

Sophisticated technologies proven over many years of service allow horizontal CMMs to work with maximum accuracy even in environments with sudden temperature changes. They operate efficiently under the same environment conditions as the production process, so there is no need for any adaptations to the workshop. This reliability, alongside the unique flexibility, performance and ease of installation and operation, make horizontal arm CMMs an attractive proposition for any manufacturer inspecting larger workpieces in a production environment.