Okuma’s 5-axis machining centers and multitasking machines deliver class-leading accuracy stability and outstanding machining capacity.

The MU-5000V 5-axis machining center maintains thermal deformation over time to less than 7 µm, while the MULTUS U4000 multitasking machine keeps thermal deformation under 10 µm for ensuring exceptional accuracy stability.

They combine high machining accuracy with powerful machining capacity for significantly boosting productivity.

MEGATech is proud to introduce the MU-500VIII from, a compact, user-friendly 5-axis machining center capable of machining workpieces up to φ700 mm × 500 mm.

Okuma’s MU-500VIII delivers process-intensive machining through 5-axis machining with class-leading accuracy stability, maximum machining space, and a compact footprint.

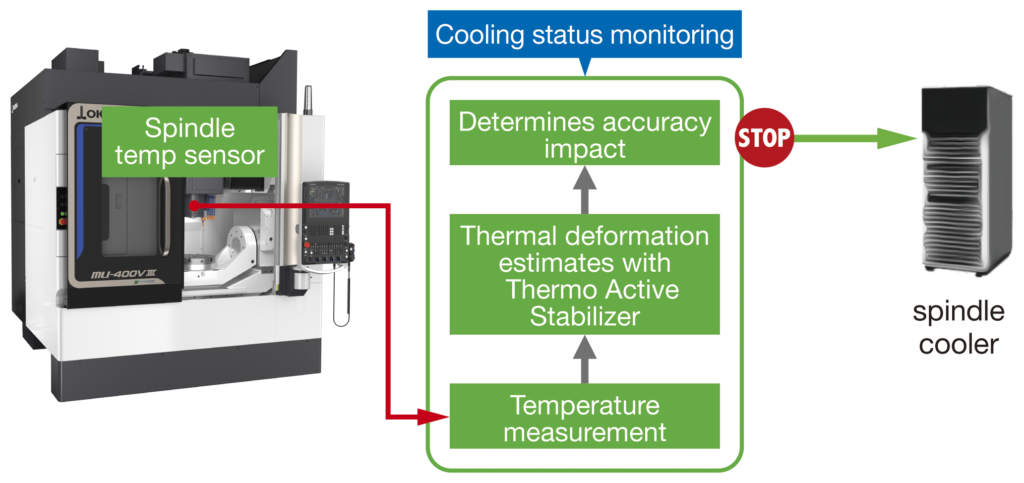

◆ World’s highest level of accuracy stability for a 5-axis control machining center

Thermal deformation over time: 7 μm max. (for ambient temperature change of 8°C)

◆Combines high productivity and high accuracy with a high level of decarbonization

Power usage reduced by 12% (Okuma estimate)

◆Provides a large machining space in a compact design

Provides 68% more machining space (compared to the same series machine when machining a maximum workpiece diameter of 600 mm)

Facilitates adoption of 5-axis control machining centers with minimal increase in floor space

Compared to the MU-400VII 5-axis control machining center with a maximum workpiece diameter of 600 mm, the MU-500VIII is a higher-end model and supports a maximum workpiece diameter of 700 mm for providing significantly more machining space.

The MU-500VIII, which has a space-saving footprint and is easy to install, and the MU-1000V series (MU-4000V/5000V/6300V/8000V), which offers even higher process-intensive machining capability, are two 5-axis control machining center model lineups that will meet the growing demand for labor savings through process-intensive machining.

Green-Smart Machine for autonomously achieving both high accuracy and decarbonization (energy savings)

The MU-500VIII combines Okuma’s intelligent Thermo-Friendly Concept, which enables the machine to autonomously maintain high accuracy, with 5-Axis Auto TuningⅡ (optional specification), which maximizes the accuracy of 5-axis machine tools in under 10 minutes. Together, these innovative technologies keep long-term thermal displacement to less than 7 µm for achieving world-class accuracy stability in a 5-axis machining center. Equipped with the energy-saving ECO suite plus system as standard, this machine uses 19% less power than previous models while maintaining the same high accuracy.

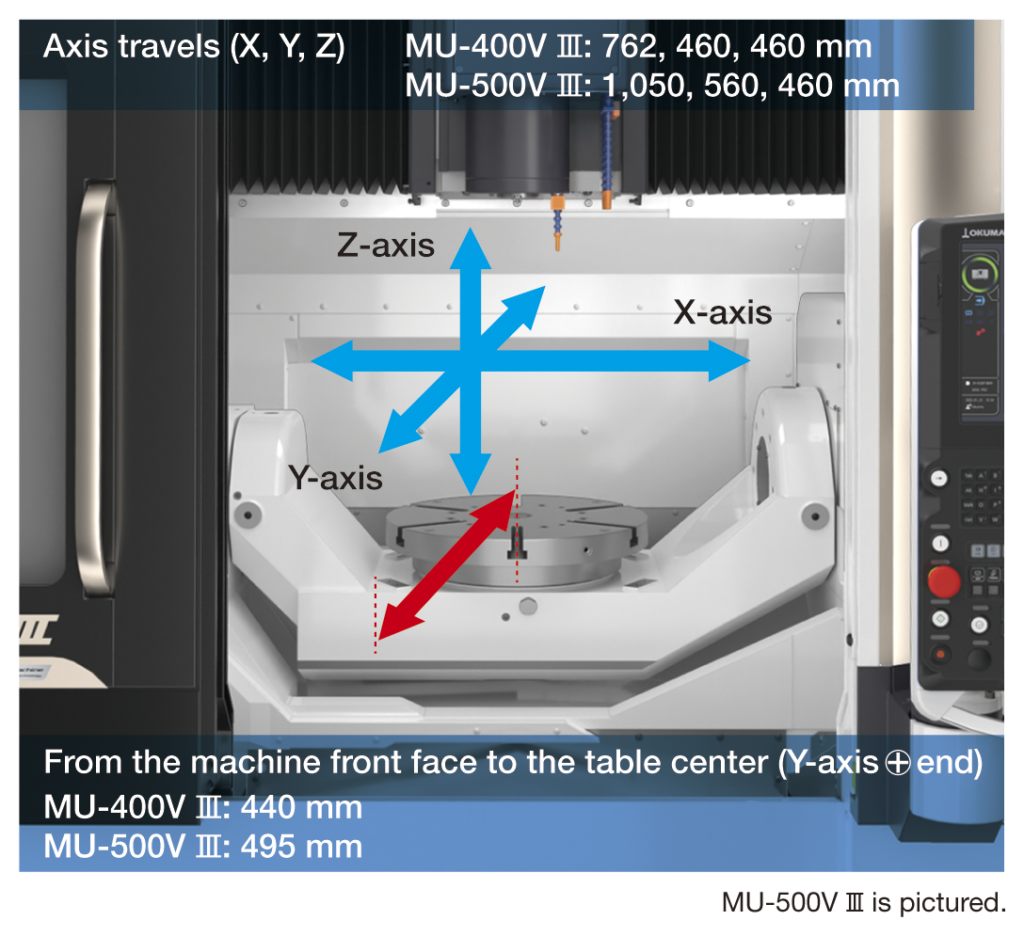

Large machining space that supports a wide variety of workpieces while minimizing footprint

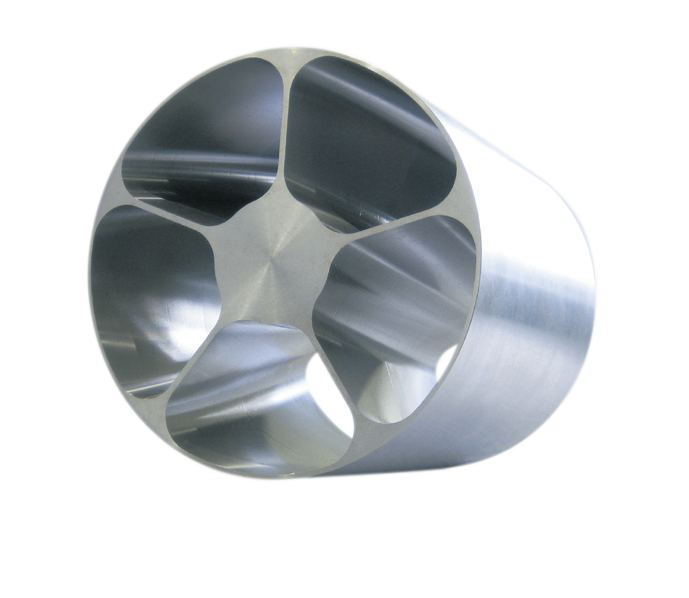

Despite a compact footprint comparable to a 3-axis vertical machining center, this machine accommodates workpieces up to φ700 mm × height 500 mm, making it easy to install in limited spaces and capable of handling a wide variety of workpieces.

It features X-axis travel: 1,050 mm, Y-axis travel: 560 mm, Z-axis travel: 460 mm, provides the largest machining space in its class, and can easily handle 5-axis machining of large-diameter workpieces (700 mm)

Powerful cutting and high accuracy rivaling vertical machining centers

Lineup of powerful spindles for heavy-duty cutting of a wide range of materials and reduced machining time

Max. rotational speed 15,000 min-1, Max. output 22 kW (optional specifications)

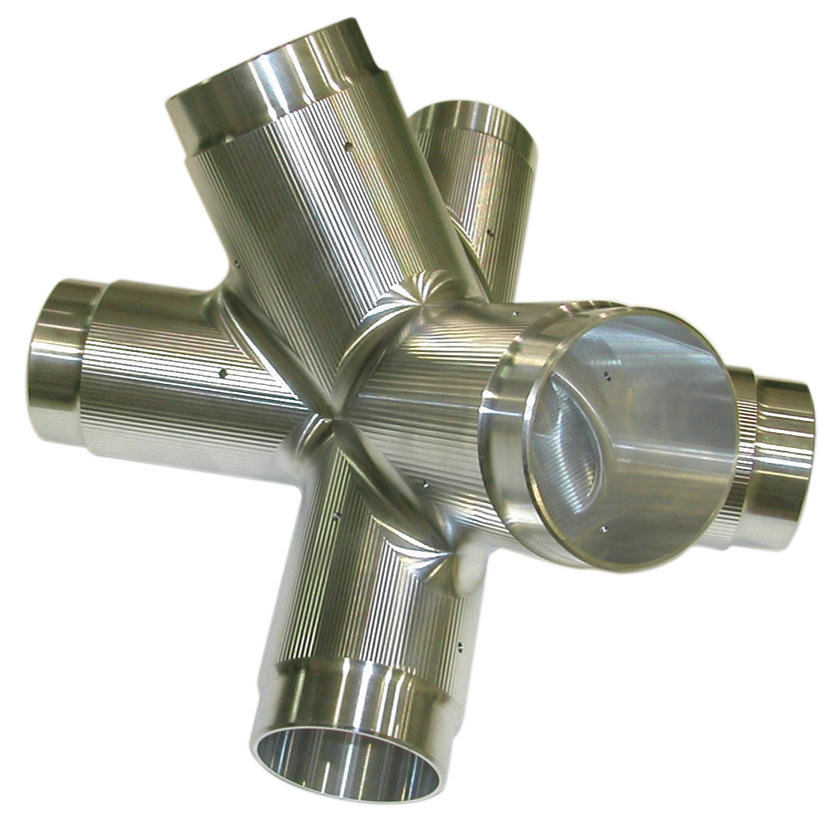

Maximum chip volume 672 cm3/min (workpiece material: steel S45C, end milling)

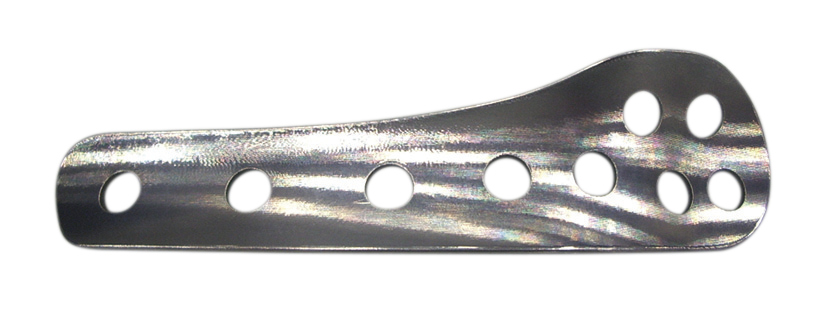

The MU-500VIII features outstanding cutting performance and is available with a powerful 15,000 min-1 spindle with a maximum output of 22 kW for enabling heavy-duty cutting across a wide range of materials. Its high-rigidity double-column structure delivers cutting power on par with vertical machining centers, while supporting stable performance under heavy cutting loads. It also is capable of multi-face machining in a single chucking for minimizing workpiece positioning errors and reducing long setup times caused by multiple workholding changes, ensuring high-accuracy multi-face machining.

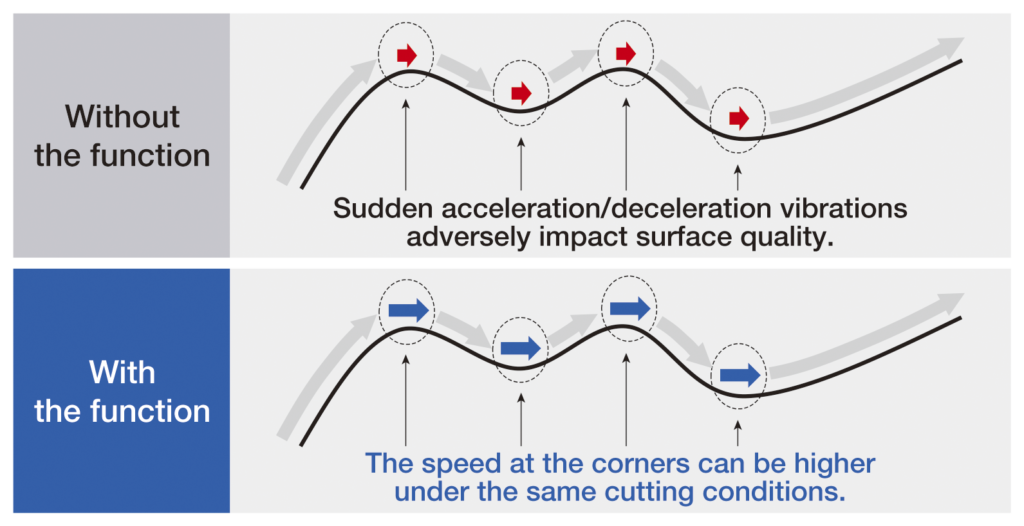

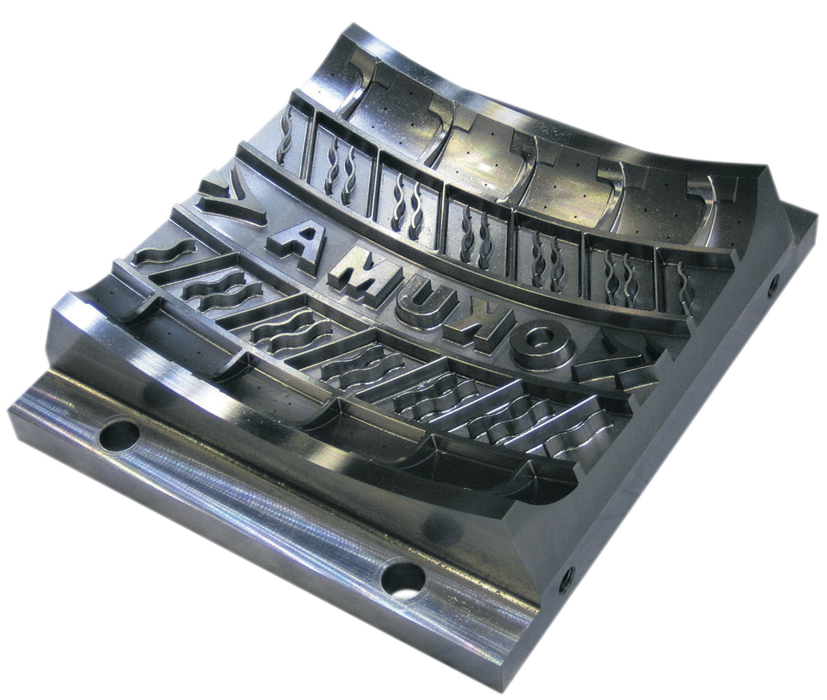

Improves the machined surface quality of dies and free-form surfaces. Hyper-SurfaceⅡ (option)

When dies and free-form surfaces are machined, streaks and edge irregularities caused by CAM data, irregular widths of tool marks in shuttle machining, etc., are suppressed with optimal axis control based on sophisticated digital technology to finish machining with high speed and high quality.

Finishing of die machining [Axis control optimal for the machining shape]

- Controlling vibration without slowing down for corners

- Shortening machining time while also improving surface quality

Minimizes operator workload and provides maximum ease of use

Ease of use that enables 5-axis machining using the same operations as a vertical machining center Trunnion table with excellent workpiece visibility during machining

- User-friendly machine structure that allows setup work in a comfortable posture. Table with excellent accessibility and that is easy to reac. Distance from machine front to table center: 495 mm

- Uses new design with a seamless blend between man and machine. Ergonomically designed work spaces for maximum ease of use by customers

Equipped with the next-generation CNC OSP-P500, the MU-500VIII is a Green-Smart Machine that combines high accuracy and productivity with decarbonization and energy savings. It meets the growing demands for both productivity improvement and carbon reduction, making it the ideal choice for customers implementing process-intensive machining using 5-axis machine tools for the first time.

Article by: MEGATech & Okuma Techno (Thailand) Ltd.<< Click Here