Customers in automotive industries require different kinds of automobiles and engines under different working conditions, including the size of the car, the type of the motor or the power of the engine to meet the demands of the market in each group. Many factors are involved such as the price of fuel, the carbon emission standards, and the tax policy of the country which can be detrimental to the automobile manufacturers, that is to say, the planning of the manufacturing force and the production line will be greatly affected by those factors.

To meet the demands of the customers, the automotive manufacturers present automobiles with the same number of cylinders but different levels of performance in each group in order to meet diverse demands. When the lifecycle of a car is shorter and the changes in the market are continuously uncertain, there must be many challenges in adjusting the manufacturing process among auto-parts manufacturers at the present moment. In order to deal with such challenges, diversity and flexibility are used as one of the parameters for traditional manufacturing process, including quality, time and cost of manufacturing. When a workpiece is complicated and specific for one purpose, the factor which will lead to the quality of manufacturing is worth considering. Therefore, the machining center which uses such system must be able to cope with flexible working conditions, respond to the operation in a timely manner and achieve precision in each workpiece for effective manufacturing.

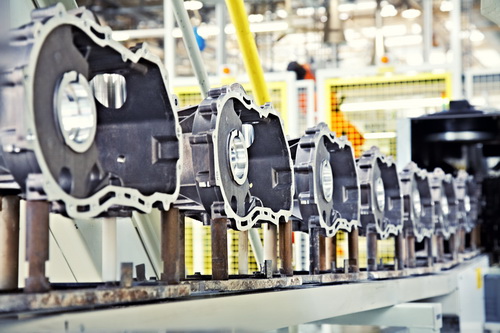

FANUC ROBODRILL α-DіB series

High-Reliability and High-Performance Compact Machining Center

FANUC ROBODRILL is the latest machining center which can give power and speed in the manufacturing process with new functions to control CNC and SERVO, resulting in higher precision in feed rate in each axis. It can punch, polish and cut highly complicated workpieces and there are functions to compensate the heat changes in a real-time manner. The calculation is done in each axis based on the data of Spindle and motor axis during the operation, resulting in higher precision in spindle and stability in working condition.

ลดเวลา Down TimeMinimizing Down Time

With longer working life and higher quality as well as automatic functions, the machining center will be maintained and guarded against damage during the operation. There is a display to give notifications when the machining center has a problem alongside basic suggestion on how to solve the problem in order to minimize the down time for troubleshooting. Smart overlap function is an intelligent system to reduce the work time by adjusting the distance between speeding during movement and milling process during the time of tool changing and moving working tables and the like.

Increasing the efficiency of manufacturing

ROBODRILL has been developed to manufacture workpieces fast with high power spindle and the internal mechanism has been designed for high stability so that the milling becomes effective. There are functions to collaborate between machines and rotating axis so that both can work at the same time effectively and there is an intelligent sensor called αiCZ to increase the speed as well as the precision without causing back-lash. Moreover, it is flexible so that a highly complicated workpiece can be manufactured and it complies with the controlling system to create workpieces for specific purposes in an effective manner.

Ease of use

The software ROBODRILL-LINKі for computer is used to control the manufacturing process. It is easy to use. It can store and display the data of the machine in a real-time manner in the form of graph. It can store parameter information to set up the management system so that there is no need to reset every time a workpiece is manufactured. An alarm message will be notified when there is a technical problem and the message will identify the spot of the problem as well as the causes and solutions to such problem in order to provide ease of maintenance and to reduce the down time.