The technologies for high-precision machining with high-speed and high-acceleration driving of feed-axis of double-column machining centers. In the proposed approach, linear motors whose stator has no magnet are adopted to the feed-axis to realize the high-speed and high-acceleration driving. In addition, the characteristic of generating little heat is necessary for this linear motor to keep out thermal deformations of the machine structure. In the proposed approach, the force pulsation of linear motor is reduced by arranging magnets and canceling effects of two sliders. As a result, the motor position can be controled with high accuracy. Moreover, the high-acceleration causes deflections of the machine structure such as a column. The deflections cause tracking errors at the cutting point of the tool, even if the motor position follows the position command correctly.

To deal with the ever increasing needs of different automatic machining conditions, various CNC machines with different functions were continuously made. But, how to speed up the exploration of new machines and meanwhile assure their quality is still a hot issue. In the viewpoints of a machine producer, how to produce a reliable machine in the way of time-saving and cost-saving seem a conflict event to each other. To solve this conflict, some following basic concepts should be aware first. To design a good structure of tool machinery, there are lots of factors which influence their precision behavior during machining. Among these factors, the original type of structure is especially crucial. In view of the development history of tool machinery for various makers, it is found that most of the machine structures were designed by experience. In the early age, it was O.K. for using the experience-based rule to design simple machine structure with low precision. However, in the high-competition environment today, this experience-based design can no longer provide enough knowledge for developing a good-quality machine which frequently requires features like low-weight, multi-function, high rigidity and at the same time possesses complex structure. Therefore, for saving development time and money, as well as introducing more solid mechanics knowledge to cope with the ever-growing requirements for designing a good machine, a rapid and efficient way in conjunction with the accumulated know-how or past knowledge are needed.

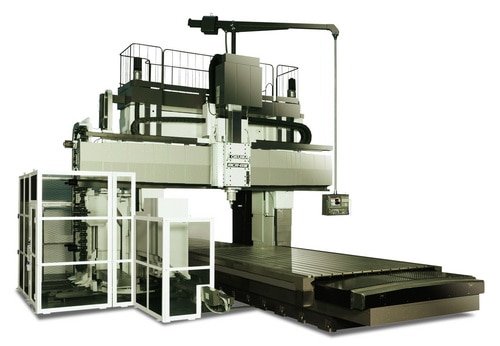

Okuma’s Thermo – Friendly Concept

Distortion of machining dimensions from thermal deformation – In the past, the main strategy for combating thermal distortion on machine tools was to limit heat generation to the minimum. The new thinking adopted in the Thermo-Friendly Concept is, as the name indicates, to co-exist with heat rather than fight it. Thermal deformation occurs in complex patterns that make it difficult to predict; however, if thermal distortion is allowed to occur only in predictable shapes, the effects of heat can be effectively canceled through correction. This is done with the use of:

- Simplified heat deformation structures

- Design technologies to make heat distribution uniform

- Highly accurate thermal deformation compensation

With this technology high machining accuracies can be maintained even without large cooling systems or extensive equipment such as temperature-controlled rooms.

Double-column machining centers and other large machine tools have large axis travel, and proportionately more deformation. There is also a tendency for distortion as a result of vertical temperature differences. At the point of machining, such deformation can have effects from several dozen microns to several tenths of a millimeter in size.

With the use of the Thermo-Friendly Concept on Okuma’s double-column machining centers for 5-sided applications, this thermal deformation can be reduced to one-fourth. Warming-up and temperature-controlled rooms are no longer needed, and steps do not appear even with continuous die operation for long hours with the initial zero offset, no matter where the workpiece is on a large table.