Manufacturing applications using computer numerical control (CNC) Double column Machine have seen a huge rise in industry. The CNC Double column Machine consists of several components, such as the static beam, moveable beam, moveable worktable, adjustable double column and overhead beams. The beams are the most significant parts of a CNC double column machine because they are responsible for the motion, accuracy and performance of the machine. Recently, significant improvements on CNC machines have been made with the advent of microprocessors and intelligent machining techniques. As a result of its robustness, the CNC machine is used frequently to produce a variety of designed components.

CNC double column machine tools have been extensively utilized in producing large components. One of the most important applications of the five-axis CNC double column machine is in the mold industry. This type of machine tool is widely used for the machining of complex components. High-accuracy CNC machine tools are required in many manufacturing industries due to the demand for precision and consistency of quality.

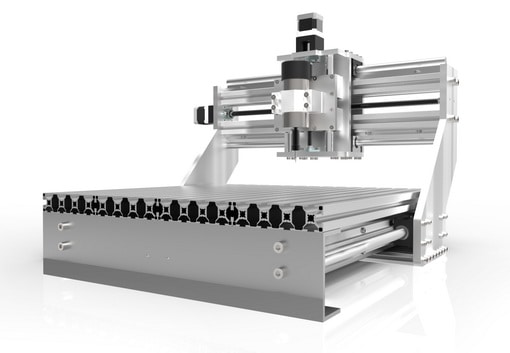

Most machines designed for cutting mold steel use a double column design because it is an easy way to move cutting torches in an X-Y coordinate system. The rail system that the double column rides on forms one axis, usually the X-axis. The double column bridge itself forms the other axis, usually the Y-axis. By motorizing each axis and coordinating the motion of the two axes simultaneously, you can move a torch in any pattern necessary to cut shapes out of mold steel. Thus, a double column design lends itself to CNC shape cutting, which primarily uses an X-Y coordinate system for programming parts. A cutting machine will ride on some sort of rail system in the X-axis. The rails are designed to provide accurate motion for the machine, and are strong enough to support the weight of the entire machine and all of the equipment mounted to it. Depending on the size of the machine, these rails can be as simple as a small strip of metal, or as complex as a recirculating ball bearing linear rail system, or as large as a railroad train rail.

A double column cutting machine will also have some sort of guiding system in the Y-axis too, which is mounted to the bridge structure itself. The Y-axis guiding system will usually be smaller than the X-axis rails, because they only have to carry the weight of a small carriage and cutting tool, not the entire double column. Double column machines may have one tool carriage or many tool carriages. Sometimes the tool carriages will each have their own drive motor that moves them in the Y-axis, and sometimes there will be only one motor that drives the Y-axis, and all of the tool carriages will be connected together by a steel band, tie rod, wire rope, or similar mechanical device. The kinematics of a moving double column system is such that it consists of two linear motors mounted along parallel slides. This enables the double column to exhibit motions in tandem with the rack and pinion system. The speed at which the robotic arms of the CNC machine reach the pre-programmed point is of utmost importance.