Overcome the limits of 5-axis machines which made your factory lose the capability to increase output and profit in the past, including the limit of complexity of forming, workpiece size, material types in the manufacturing process.

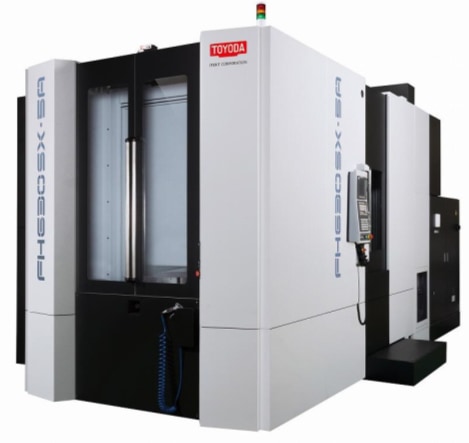

TOYODA Has Developed Machining Center FH630SX-5A with Flexible Swivel Spindle

TOYODA would like to introduce its flagship machine which is launched in 2019 to increase the manufacturing capability as well as maximum opportunity for completion in various industrial sectors such as aircraft, oil and gas, construction, agriculture and transports.

TOYODA has developed 5-axis machining center FH630SX-5A which can deal with workpiece up to ø1,170 x 1,600 mm. in size, the biggest at the current market. Moreover, it comes with the ability to mill different kinds of workpiece such as aluminum and titanium with Flexible Swivel Spindle which can rotate up to 230 degrees. It also features driving mechanism with C-axis spindle to cope with a heavy and big workpiece. The spindle is installed in the perfect location and the robust machine structure means that it can mill a workpiece in a vertical manner with 300 mm away from the center of the palette, making its working space wider.

FH630SX-5A comes with a 15,000 rpm spindle with torque up to 525 Nm and it can cover metal workpiece which requires low to medium rotation speed and it can cope with aluminum workpiece which requires high rotation speed and high axis movement. There is also an option of a 8,000 rpm spindle with torque up to 1,088 Nm to mill very strong and solid metal such as Inconel. The maintenance of spindle which crashes is easy and quick thanks to Spindle Cap of TOYODA which significantly reduces the dead time for customers and reduces maintenance cost significantly