Article by: Thiti Wongthanasak Managing Director, UNI ARC Co., Ltd.

Spatter is a common unwanted side effect occurrence in gas metal arc welding (GMAW) which realized as a problem of welding causing difficulties for the process after welding by create more work to increasing clean up time. To minimize spatter, there are many factors that need to be controlled such as gas, wire, surface of material or workpiece, torch angle, grounding, consumables, welding atmosphere, and so on. Nevertheless, the key point, we know that the main reason caused spatter is the relationship between amperage and voltage which imbalance. This is usually happened when the welding voltage is too low, or the amperage is too high for a given wire and gas combination.

The latest robotic welding technology called “Synchro Feed GMA Welding System” or Synchro Feed which innovated by OTC (Daihen) especially designed for significant spatter reduction with high-speed welding is now popular among the manufacturers who face with spatter problem.

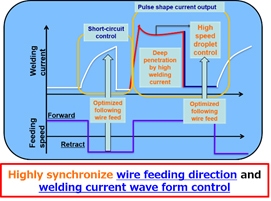

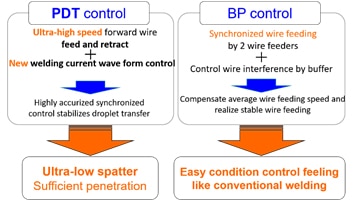

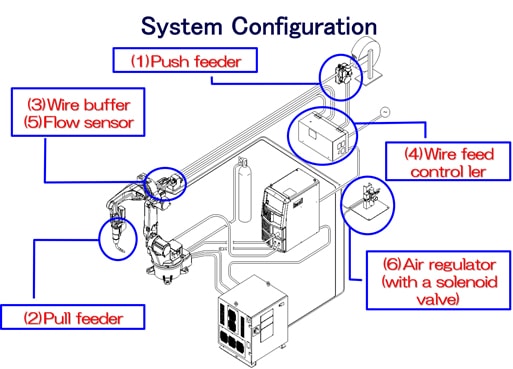

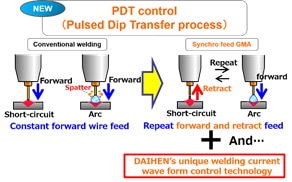

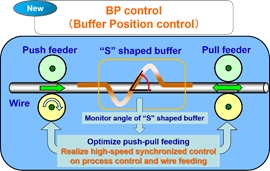

This innovation is the combination of the new technology PDT Control (Pulsed Dip Transfer process) developed on welding process control technology and BP Control (Buffer Position Control) developed on robot control technology by synchronization between wire feeding controller and current waveform controller.

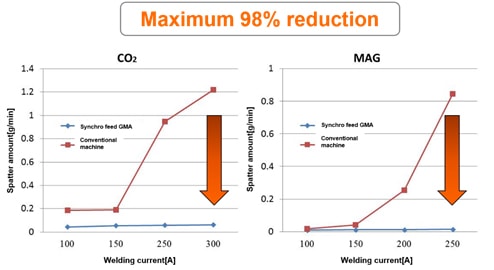

This combination makes Synchro Feed become the new welding system for robot which capable to reduce spatter up to 98% when compare to conventional welding system.

The innovation of “Synchro Feed GMA Welding System” is unrivaled robotic welding technology which is now available.

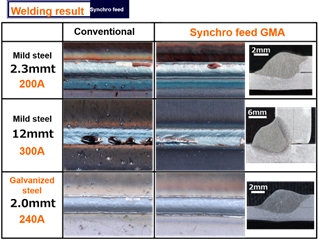

Even welding current is at 300A with normal shield gas like Co2, Synchro Feed capable to provide ultra-low spatter because rapid wire feed control has an excellent tracking capability with the wire extension. This is also ensured very low spatter even during weaving.

The remarkable feature by Synchro Feed is not only for spatter reduction but many welding excellent outcomes which cannot be easily provided by conventional welding such as super high-speed welding, deep penetration on a medium thick plate, delivering high-quality welding on a very thin plate. The system itself can apply to a wide range of applicable materials for example mild steel, stainless or even galvanized steel.