High powers can be achieved at lower costs by selecting optical fiber that maximizes absorption. However, excellent beam quality with high power and the best cost performance requires understanding choices among extra-large-formats.

Fiber lasers and amplifiers have improved vastly over the past decade as improvements in active and passive fibers, diodes, and various fiber-optic components have progressed to mature technology platforms. Fiber lasers capable of high output powers (peak and average powers) while maintaining diffraction-limited beam quality have been made possible by the continued development and engineering of fibers, and in particular, extra-large-area fibers.

Extra-large–format of laser supporting a few modes provide a larger fundamental mode area for power scaling and, with proper selection of the fiber, can provide excellent beam quality. Selecting extra-large -area fibers for a given application requires careful consideration of fiber parameters, desired laser performance, manufacturing costs, and product reliability. The fiber choices a laser manufacturer should consider for application-dependent optimal laser performance.

Several extra-large–format of laser options are available to laser manufacturers. Understanding the trade offs and performance impacts of the fiber properties and characteristics is important for selecting the most appropriate fiber for the specific application. Selecting an fiber laser with high absorption (providing shortest fiber device length) could reduce the overall laser product cost, but these fibers could make it difficult to achieve good beam quality. On the other hand, choosing a fiber with slightly lower absorption may enable excellent beam quality at the highest of powers. Some manufacturers have developed laser cutting systems at extra large product, which will reduce workflows and process that lead to further assembly errors. This is particularly attractive for manufacturers in the shipbuilding and aerospace industries.

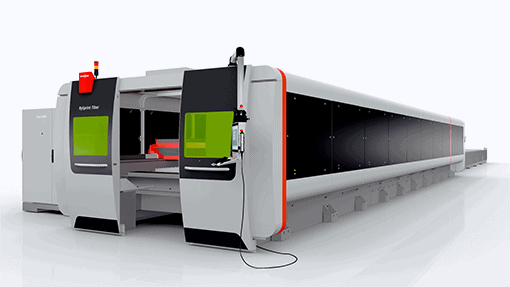

BySprint Fiber: Now in the 12-meter format

Bystronic is expanding the BySprint Fiber laser cutting system with the 12020 extra-large format. This increases laser cutting productivity and the diversity of cutting applications.

More sheet metal, more parts, more variety. Extra-large-format laser cutting systems enable users to stand out against competitors. Hence, Bystronic is expanding the BySprint Fiber laser cutting system with the 12020 format. The machine can be equipped with the Fiber 3000, 4000, or 6000 laser sources, depending on the user’s requirements.

Thanks to the new extra-large format, users can process metal sheets up to a length of 12 meters using the BySprint Fiber. On the one hand, this increases the machine’s productivity, because large metal sheets allow the cut parts to be nested more efficiently. On the other hand, this also significantly reduces undesirable raw material offcuts.

The new extra-large format also increases the variety of cutting applications on the BySprint Fiber. If required, large-format metal sheets allow large parts to be cut in addition to diverse small parts, without requiring the machine to interrupt the laser cutting process. This provides a competitive advantage that laser cutting systems in the common standard formats cannot offer.

In addition to cutting applications with extra-large metal sheets, the 12020 format also enables smaller sheets to be processed by lining them up on the BySprint Fiber’s long cutting table. Users can simply prepare sufficient raw material, in order to subsequently allow the fiber laser cutting system to cut the sheets consecutively without interrupting the cutting process for a longer period of time.

One fiber laser, all options

- Available in models 3015, 4020, 6520, 8020 and 12020. This means that sheet metal up to 12 × 2 meters in format can be processed quickly and economically

- Unparalleled high parts production and first-class cutting quality for thin to medium thick sheet metal, depending on laser power

- Additional functions (Power Cut Fiber, Cut Control Fiber, Nozzle Changer, Detection Eye) and automation options increase the application scope to a maximum