The need for fast, precision, durability, and energy-efficient solutions in these projects further drives the demand for advanced sheet and tube metal processing machines. With these in mind, MEGATech explores the sheet and tube laser cutting solution from Bodor Laser and sees how this bestseller is the best choice for metal processing manufacturers who support the construction industry.

Why You Need a Laser Cutting Machine ?

The sheet and tube laser cutting machines offer many advantages compared to the other processing methods. These advantages include but are not limited to;

- High Speed and Precision: Laser cutting machines can cut sheet and tubes quickly and with great accuracy, making them ideal for high-volume production and intricate designs.

- Versatility: The machine can handle a wide range of materials, including metals, plastics, and even some composites, and can be adapted to a wider range tube diameters and thicknesses.

- Automation: Laser cutting machines are highly automated, reducing the need for manual labor and increasing efficiency.

- Low Maintenance: Some laser cutting machines, particularly fiber lasers, have low maintenance requirements due to their solid-state design and fewer moving parts.

- Reduced Waste: Laser cutting generally produces less waste compared to other cutting methods, making it a more environmentally friendly option.

The Bodor Laser Offers Fast ROI

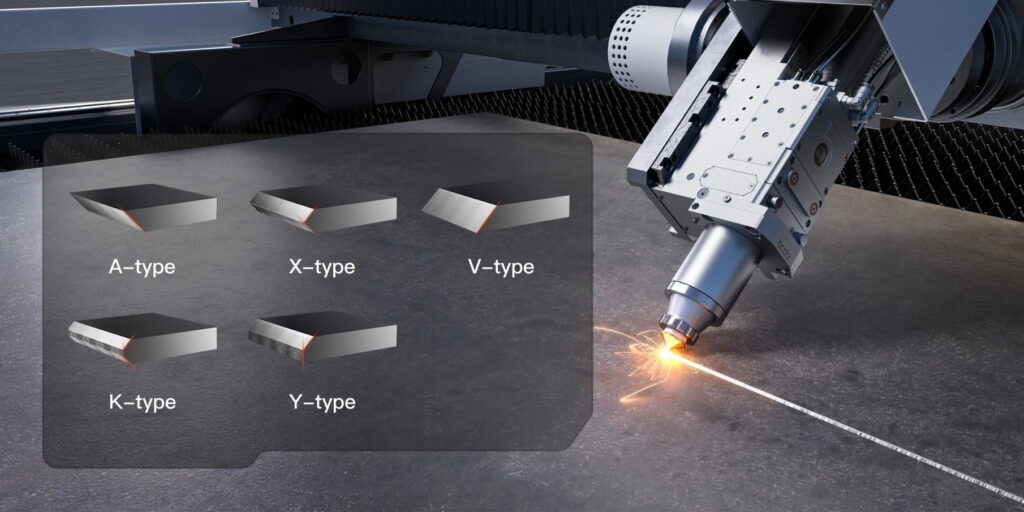

Bodor Laser offers sheet and tube laser cutting machines covering power ranges from 1500W to 12000W, with a maximum cutting diameter of up to 530 mm. The machine can provide professional, efficient, and mature customized solutions for the sheet and tube cutting required for medium to large infrastructure. The machines are specifically designed to achieve true zero residual cutting, reduce postprocessing cost and material waste.

Bodor Laser presents 3 lineup; the G, M and K series which suitable for serving the demand of the region.

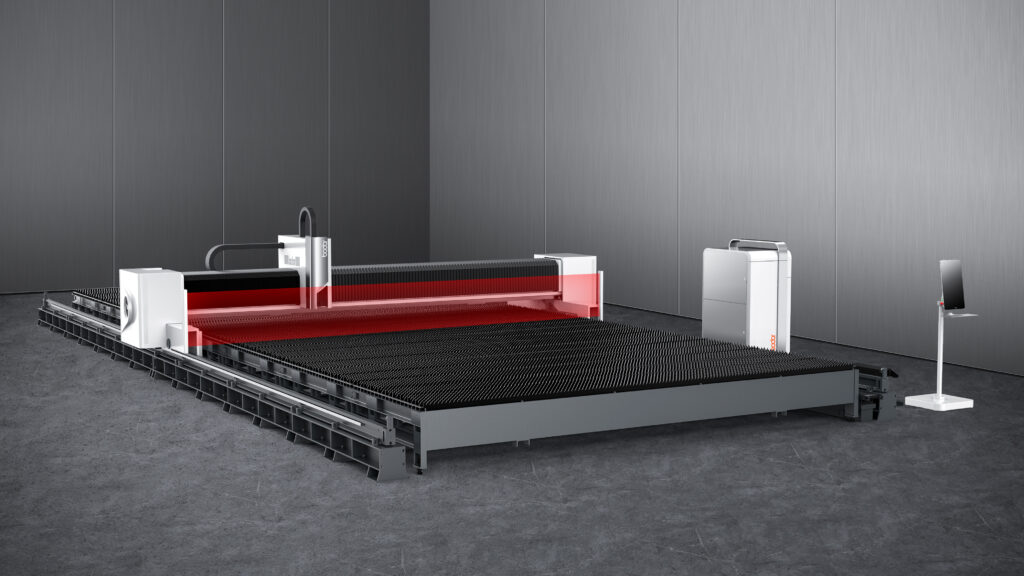

The G series:

The G series offers super adaptability allowing for the use of an existing cement base or a Bodor-provided base, significantly reducing foundation costs and enabling quick setup by utilizing existing plasma cutter foundations, thus eliminating the need to replace the foundation for laser processing equipment. This significantly saves installation and validation time and labor costs, allowing you to quickly enter production.

The G series enhances cutting efficiency with features like 12kW-60kW high power options, faster cutting speed and narrower kerf compared to plasma and flame cutters, significantly boosting productivity and reducing material waste. The ultra-large format provides broader customized choices. A 12-meter+ bed frame offers significant efficiency advantages. If you’re looking to upgrade your capability to laser sheet cutting, the G series makes the perfect choice.

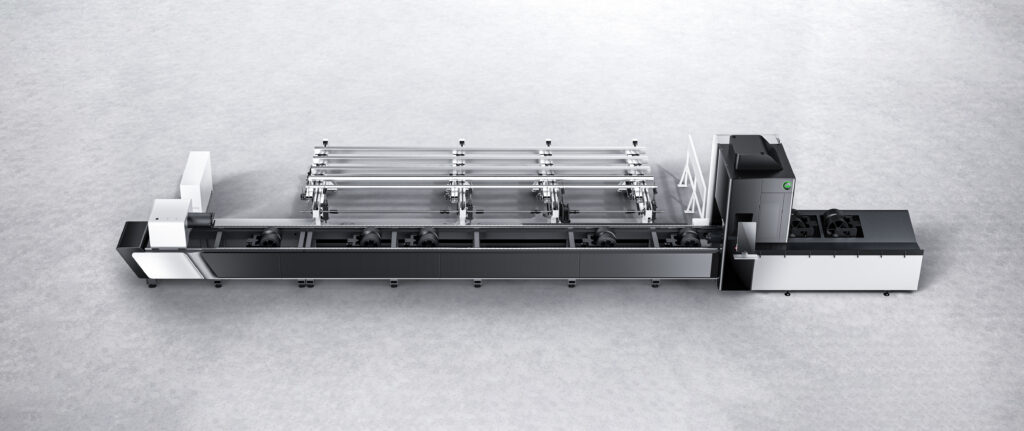

The M Series

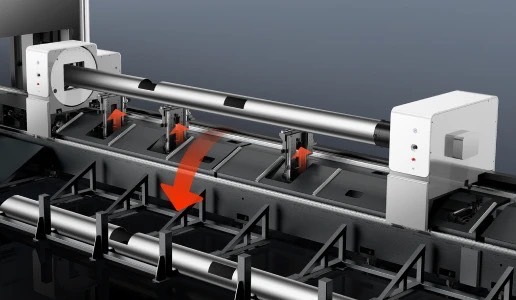

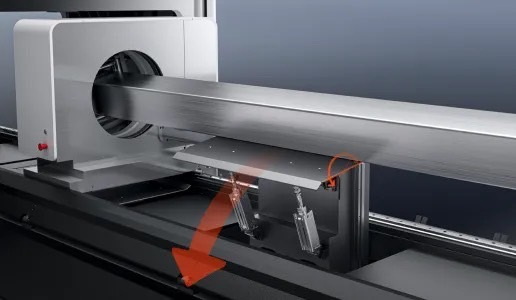

The M Series completely revolutionizes the process and efficiency. When cutting tubes, it can simultaneously initiate a new round of loading or finish the previous unloading, bringing about an unprecedentedly efficient and smooth processing experience.

The machines offer excellent loading capacity, fulfill diverse, hard-core cutting needs. This model is ideal for heavy metal tube processing where M5 is capable of cutting tubes with diameters up to 530 mm.

The M Series enable zero excess material processing, minimize manufacturing waste from the source. During operations, M5 will help you utilize every piece of material to the largest extent possible, reducing waste and improving cost-effectiveness. The machine comes with safety enhancement providing a secure operating environment.

M5’s 4-chuck mechanism ensures high-quality cutting without manual intervention, ensuring a hands-free operating environment with lower human costs. With all said, the M Series is the best choice when it comes to handling heavy-duty cutting with smooth operation.

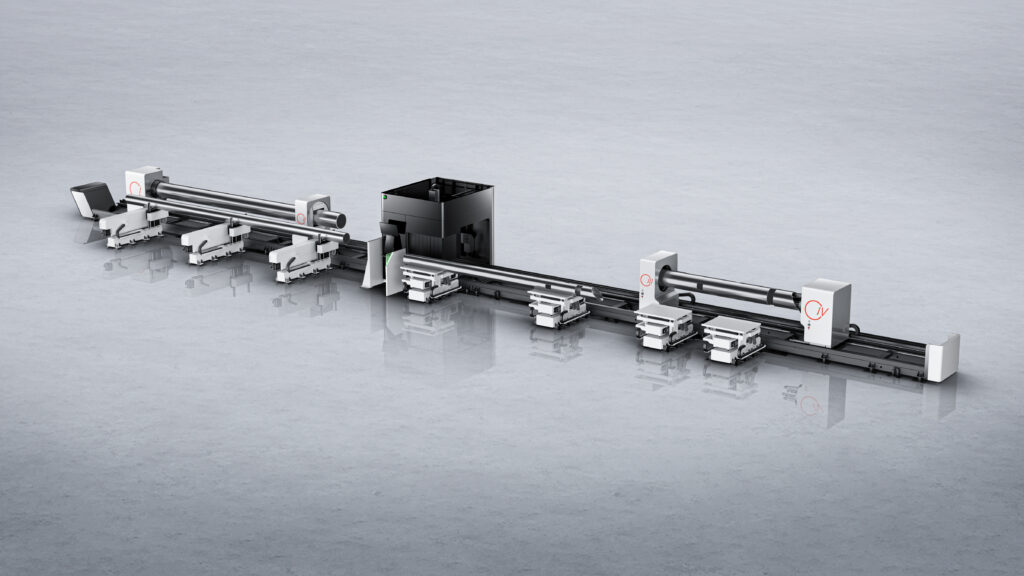

The K Series

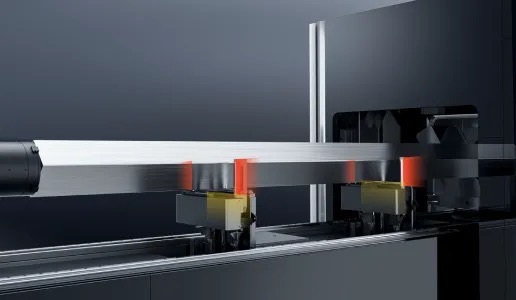

The K Series features industry bestsellers and the easiest operation for tube laser cutting machines. Bodor has launched the K Series to address the issue of high operational barriers in the market. This machine integrates features such as high-speed chucks, fast clamping response in 2S, ultra-short tail material, and a one-click start. It is designed to provide a simple, safe, and environmentally friendly tube-cutting solution.

The K series achieves a maximum loading speed of 100 m/min and a chuck rotation speed of 130 r/min. It realizes rapid cutting without compromising on cutting speed. The optional loading devices, K-Loader and K-Trans, are available to boost customers’ automation level. It adopts high-performance bus servo motors, significantly improving processing efficiency and ensuring the fastest return of investment. The advanced pneumatic chucks allow for complete clamping in as fast as 2 seconds.

It is designed for easy to disassemble allowing for quick and low-cost maintenance. All in all, the K series offers the best choice for those who need both high efficiency and low operating costs when process various types of metal tubes into complex shapes.

Article by: MEGA Tech & OTA ENGINEERING (THAILAND) CO., Ltd. << Click Here