Following the successful completion of the Dealer Seminar 2025 hosted by Tungaloy-NTK Thailand, the next day featured the Asia Seminar 2025—an important platform for knowledge sharing and experience exchange among over 100 dealers and customers from across the Asia-Pacific region, including Australia, Singapore, Malaysia, Indonesia, and more.

The primary objective of this event was to showcase the world-class manufacturing capabilities of Tungaloy’s production facilities up close, while also strengthening relationships between Asian distributors, customers, and the factory team. This event marks another significant step toward fostering long-term cooperation and sustainable business development throughout the region.

The key highlights of the event included the unveiling of new products, accompanied by live machining demonstrations that showcased their real-world performance and capabilities. One of the most impressive activities was the guided factory tour at Tungaloy’s Iwaki facility, featuring four main stations that demonstrated the company’s state-of-the-art, world-class manufacturing processes. Another significant moment was the Dealer Awards Ceremony, honoring top-performing partners for their outstanding sales achievements in 2025.

MEGA Tech was proud to explore and capture these remarkable highlights throughout the event.

The event began in a warm and welcoming atmosphere, The program officially opened with a heartfelt speech by Mr. Satoshi Kinoshita, President and Chief Executive Officer of Tungaloy Corporation. In his address, Mr. Kinoshita shared the company’s rich history and the guiding philosophy that has shaped Tungaloy over the decades. His words reflected the company’s strong vision and unwavering commitment to advancing technologies that meet the evolving needs of modern industry in a sustainable way.

Tungaloy Corporation originated from the development of cemented carbide by Toshiba in 1929 and became an independent entity as Tungaloy Corporation 2004. It joined the IMC Group, the world’s second-largest cutting tool group, in 2008. In alliance with NTK, Tungaloy offers a full range of advanced cutting tools—PVD, CVD, CBN, PCD, ceramic, and cermet—for all material types and machining needs.

With 98 years of experience, Tungaloy has made major global strides, including 650 patents and 1,500 new products launched in just the past five years.

Focused on sustainability, Tungaloy drives CO2e reduction through:

- Dispose: Tools like TungForce-Rec cut raw material waste by over 99%.

- Use: ADDMultiTurn lowers energy use by 55%.

- Produce: Products like ECO 09 help reduce production emissions by 17%.

Additional eco-initiatives include solar energy (cutting 82 tons of CO2/year), banana paper (replacing 400,000 sheets), and reduced plastic packaging (580 kg/year).

MEGA Tech had the distinct honor of conducting an exclusive interview with Mr. Satoshi Kinoshita, President and Chief Executive Officer of Tungaloy Corporation, who shared his strategic perspective on the company’s direction amidst the evolving global manufacturing landscape.

Mr. Kinoshita highlighted that while the automotive industry remains a primary market, particularly in Japan and Thailand—accounting for 40–50% of sales in Japan—Tungaloy adopts a diversified approach, recognizing the unique strengths and industrial focuses of different countries. In Thailand, for example, he sees strong growth potential in emerging sectors such as artificial intelligence, data centers, and high-precision component manufacturing.

He emphasized Tungaloy’s commitment to enhancing customers’ overall productivity and cost efficiency, not merely through reducing tooling costs (which comprise only around 3% of total production costs), but by enabling significant gains in machine efficiency. Reducing machining time by half, he noted, can lead to overall cost reductions exceeding 20%. This strategy also contributes meaningfully to sustainable manufacturing by minimizing energy and resource consumption.

Tungaloy’s strong global presence allows it to collect real-time customer feedback and respond swiftly to market needs. With more than 50 new product launches annually, significantly outpacing competitors, the company continues to lead in innovation tailored to the demands of modern industries. These include lightweight manufacturing, additive manufacturing, and high-precision casting.

“Although newer production systems may reduce the reliance on conventional cutting tools, customers increasingly seek comprehensive solutions aligned with next-generation technologies,” Mr. Kinoshita concluded. “At Tungaloy, we are fully committed to meeting those expectations with speed, precision, and innovation.”

Following this, we present the special “New Product Line” session Led by Mr. Kawaguchi Tatsuya, Chief Technical Officer, Tungaloy Corporation who will take you on a journey through the latest technologies in each product category and share in-depth case studies that have proven to significantly and tangibly enhance production efficiency.

AddForce Millline The latest milling tool lines for accelerated machining

1.DoTwistBall : The perfect solution for profile machining

R-shaped face milling cutter with chamfered cutting edge for profiling applications. The uniquely twisted insert geometry ensures stable and secure clamping. Two types of inserts can be used with the same milling cutter body – both R-shaped inserts and high-feed inserts

2. DoFeed : New generation feature high feed accelerated face milling

Insert has 4 wide cutting edges with high positive rake angles, which provide a smooth cut with low cutting forces. The DoFeed tools perform easily even on long overhang applications, while assuring high feed, vibration feed milling range, resulting in smooth large-depth machining. For improved surface finish, the operation requires only one wiper insert on the cutter for significant results. The O3 insert is used with small diameter tools for penetrating narrow spaces in large depth machining. The tools are characterized by insert density, resulting in higher table feeds and metal removal rate machining.

3. MillQuadFeed : Heavy-duty high feed face mills with 4 cutting edge inserts

The unique insert design allows for a change in the approach angle. This insert features a wavy cutting edge that makes heavy-duty milling easier. The tool’s new air holes assist in efficient chip evacuation and control the chip flow, consequently avoiding interference with the machined areas. This robust insert is anchored in a unique pocket design, which provides high stability, enabling heavy-duty cutting.

4. DoTripleMill : General face milling applications for diverse materials with cost-effective advantages.

The tool body features a specially designed dovetail-style insert seat, ensuring enhanced insert stability and extended tool life. Additionally, the insert seat is compatible with 3 insert shapes: square, octagonal, and round.

For applications requiring deep cutting depths, the square insert with 8 cutting edges is the optimal choice. Its concave cutting edge design promotes efficient chip formation and smooth chip evacuation. The octagonal insert, offering 16 cutting edges, is ideal for face milling and significantly reduces tooling costs. Meanwhile, the round insert with 8 cutting edges is suitable for high-feed or deep face milling operations. Its wavy cutting-edge design minimizes cutting forces and helps reduce thermal damage at the cutting edge.

5. DoForceTri : New cutter for 90° shoulder milling

The cutter is mounted with economical double-sided triangular inserts with 6 cutting edges. The concave cutting edge geometry and the positive rake angle produces barrel-shaped chips that easily evacuate from the machined areas. The DoForceTri tools perform full-depth, 90-degree shoulder milling, as well as slot milling operations. The wiper insert features cutting edges with a wiper design which improves surface finish. The saw-like cutting-edged inserts are clamped on the same cutter and mainly used with long extended holders. Chip splitting reduces cutting forces and avoids vibrations.

DrillMeister High-Productivity Indexable Solid Drills

Drilling operations can be time-consuming, so having the right tool is critical to avoid downtime. The new DrillMeister indexable solid carbide drill is engineered to maximize productivity and minimize machine stoppages.

Its innovative clamping system reduces strain while ensuring secure insert retention with a dovetail design that prevents pull-out—delivering smooth, uninterrupted cutting and extended tool body life.

With two highly effective Ultimate edge geometries, DrillMeister offers self-centering and strong cutting stability without the need for pre-holing, significantly reducing cycle time. It’s suitable for a wide range of materials and covers diameters from 6 mm (0.24″) to 25.9 mm (1.02″) in 0.1 mm increments.

A specialized PVD coating enhances wear resistance for improved performance and longer tool life.

In addition, DrillMeister offers up to five head types to choose from — DMP, DMC, DMF, DMH, and DMN — covering a wide range of applications and materials, from standard workpiece materials to flat-bottom drilling. It’s truly an all-in-one solution.

With hundreds of tool configurations available, DrillMeister delivers exceptional results—up to 60% faster machining and 20% longer tool life compared to competitors.

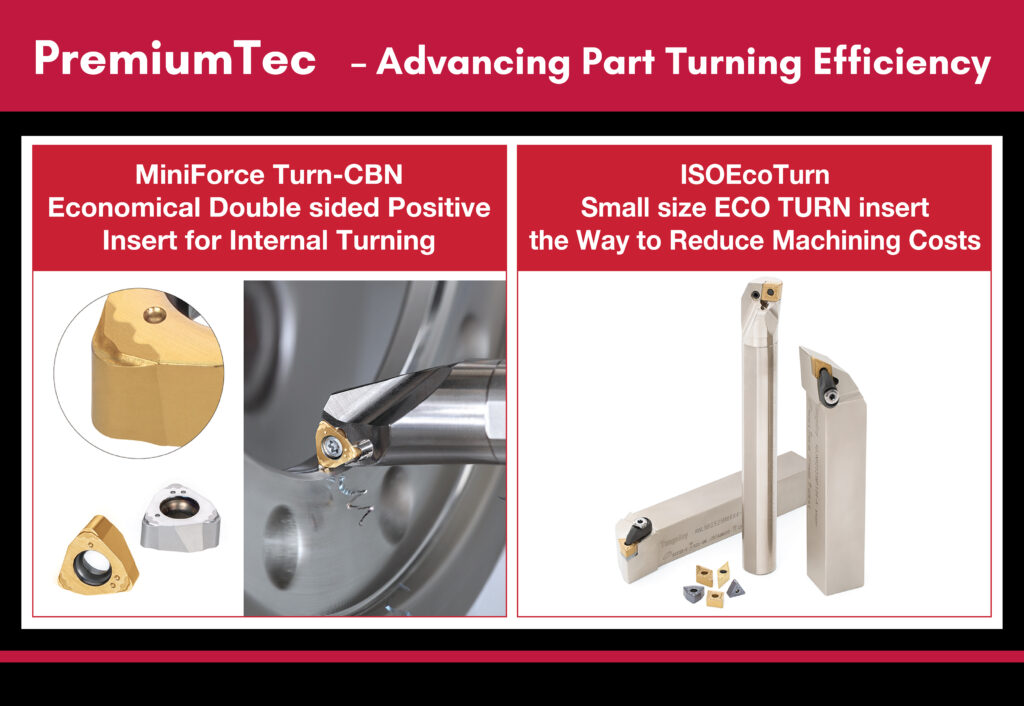

PremiumTec – Advancing Part Turning Efficiency

During the seminar, Tungaloy proudly introduced PremiumTec, their complete product line specifically designed for turning applications. This variety of insert grades features product design and coating innovation, aiming at improvement in productivity and tool life, and covering a wide range of materials. The new range features special PVD and CVD coating grades which combine a super hard top layer of Al2O3 with post-treatment and a special substance design, which together significantly improve wear resistance, thereby increasing overall productivity and extending tool life.

Key Features of PremiumTec Technology

- A smoother surface combined with a robust coating layer improves resistance to shock and edge breakage during cutting operations.

- The smoother surface prevents oil and metal chips from sticking, effectively addressing common issues in steel and alloy turning applications.

- With excellent vibration resistance and fracture toughness, it ensures efficient entry and exit during cutting and withstands demanding conditions.

MiniForceTurn CBN for Outstanding Chip Control

MiniForceTurn is a cost-effective and efficient double-sided positive insert designed for internal turning. It now features CBN inserts that provide added strength and stability under demanding cutting conditions. The CBN tip offers exceptional hardness, making it ideal for machining hardened steel, metal alloys, and other specialized hard materials. Additionally, the insert comes with a specially designed chipbreaker to ensure excellent chip control, reducing issues in both finishing and semi-finishing operations.

ISOEcoTurn for Cost Saving

A highlight for cost-conscious manufacturers was the ISOEcoTurn, a unique, thicker size turn insert designed to be the best choice for reduced machining costs. Its thicker design offers maximum strength and durability compared to standard inserts. The innovative cartridge set allows the use of ISOEcoTurn inserts without needing to swap the tool holders. For example, the standard CNMG 43., a holder with lever clamping, can be converted to the ECO size of CNMG 33 and WNMG 33 inserts by simply replacing the lever and adding the cartridge.

Expanding the Horizon – Advanced Material Solutions and Specialized Grades by Tungaloy-NTK

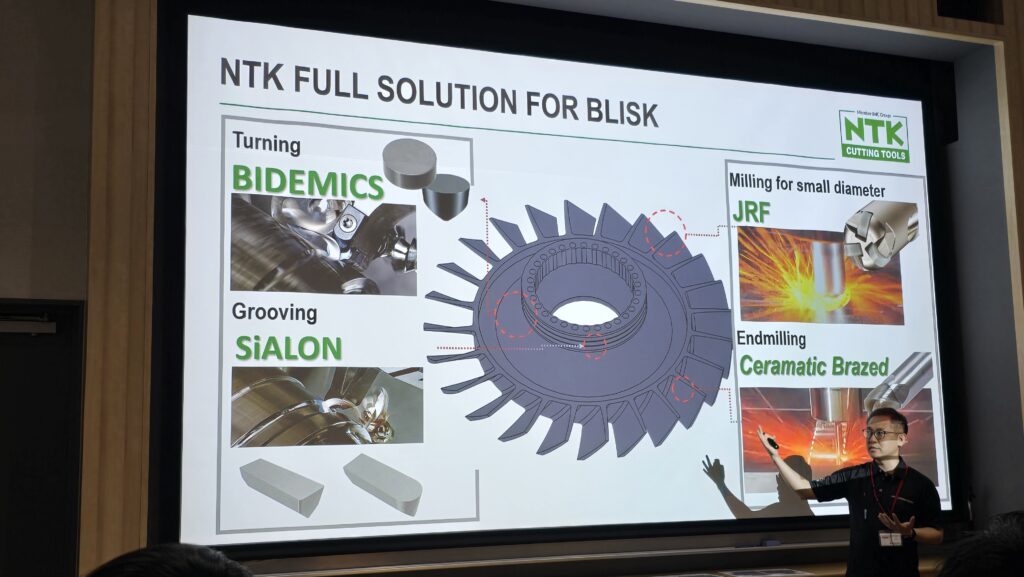

Beyond the specific milling and drilling innovations, the seminar also provided a comprehensive overview of Tungaloy’s broader material solutions, particularly highlighting the powerful alliance with NTK. As a combined force, Tungaloy and NTK position themselves as a comprehensive full material supplier, Led by Mr. Eisuke “Ace” Nagaoka, Marketing Division, Product Group, Assistant General Manager, offering cutting-edge solutions tailored to every material type. This synergy allows Tungaloy to provide optimal grade cutting tools, including alumina-based, silicon nitride (SiAlON) – ideal for higher feed rates, whisker – a conventional solution, and bidemics – a unique NTK grade designed for higher speed applications. These diverse grades ensure Tungaloy can meet every machining need across a wide range of industries, including aerospace for Heat Resistant Super Alloy (HRSA) solutions, automotive for cast iron and hardened materials, and mill rolls for hard materials.

Specialized Solutions for Demanding Industries

Aerospace (HRSA Solutions)

We learned how Tungaloy’s HRSA solutions are critical for aircraft engine components such as fans, low- and high-pressure compressors, low- and high-pressure turbine discs, combustion cases, and turbine cases, used in both turning and milling applications. A compelling case study presented involved Inconel 718, where Tungaloy’s solutions resulted in 1.85 times higher productivity, effectively offering double the tool life. Furthermore, new milling solutions are offered with the JRF series and Ceramatic, enhancing performance in these challenging materials.

Automotive Industry

For the automotive sector, Tungaloy emphasized superior ceramic grades for roughing cast iron in turning and milling operations. For instance, solutions for gray cast iron FC250 demonstrated 1.2 times better productivity and 1.5 times longer tool life. For FC200, Tungaloy’s offerings achieved an impressive 80% reduction in insert cost, while also addressing issues like CBN getting heat shock in wet conditions. When dealing with hardened materials, unparalleled ceramic grades are crucial for high productivity. Tungaloy showcased examples with SCM415 and SCr420H, which delivered 2 times longer tool life.

Mill Roll Industry

The seminar highlighted Tungaloy’s high-productivity ceramic grades specifically for mill roll machining. The HC7 grade is utilized for hardened materials, while HC5 was developed for hard turning applications in mill rolls. The HC2 grade offers excellent cost performance compared with CBN. For ferrous metals, Tungaloy’s ceramic FSW (Friction Stir Welding) tools provide high performance in friction stir welding of high-melting point metals, resulting in a substantial cost reduction compared to conventional tools. For light metals, carbide FSW tools are also available for friction stir welding of low melting point metals.

Miniature Tool Line and Advanced Coatings: The PMS NTK650

Tungaloy also presented its miniature tool line, offering a wide range of PVD grades to cover any miniature machining need. A main highlight was the PMS NTK650, which utilizes the latest HiPIMS (High Power Impulse Magnetron Sputtering) coating technology. This advanced coating offers significantly enhanced surface smoothness and prevents defects in the film. The smooth surface, free of droplets, enables overall performance improvement and achieves long tool life for Nickel-base alloys, as well as M- and P-class alloys. Additionally, the NTK650 features several benefits including coating peeling prevention, reduction of built-up edge, prevention of defects inside the coating film, and achievement of long and stable tool-life.

The in-depth presentation of Tungaloy–NTK’s latest product innovations extended beyond cutting-edge technology—it served as a true source of inspiration. Through live demonstrations of advanced milling, drilling, and turning processes on actual workpieces using state-of-the-art machinery within the Tungaloy showroom, participants witnessed firsthand the tangible power and potential of next-generation manufacturing solutions. The path toward Industry 4.0 is no longer a distant vision—it is already a reality. This experience reaffirmed the belief that Thailand’s manufacturing sector is fully capable of advancing with confidence, resilience, and boundless potential.

Factory Tour: A Deep Dive into Innovation! Discover the Cutting-Edge World-Class Production of Cutting Tools”

We began our journey into the world of cutting-edge technology with an in-depth Plant Tour, where the Thai delegation was divided into two groups to ensure everyone could closely and comprehensively experience the production process. The tour was led by key presenters from Tungaloy–NTK Thailand: Dr. Nitichai Jitkusanroongruang (Marketing Executive & Product Specialist) and Mr. Thammanit Tintisawee (Application Manager), who provided detailed explanations at each stage of the process alongside expert engineers from Japan. Throughout the tour, participants gained valuable technical insights presented in a clear and accessible manner, making the entire experience both enriching and truly inspiring.

The first area we visited was the production process of CBN (Cubic Boron Nitride) insert production line offered an impressive insight into a world-class manufacturing process that seamlessly integrates advanced technology with rigorous quality control. The process begins with high-precision blending of raw powders to create CBN blanks with exceptional purity and uniform microstructure. These blanks are then subjected to Vacuum Sintering at extremely high temperatures, followed by Ultra-High Pressure Sintering. This step is critical in forming a dense, super-hard CBN crystalline structure that ensures outstanding durability and cutting performance. Each insert undergoes thorough quality inspection, with particular attention to hardness and thickness, ensuring consistent performance even in the most demanding high-speed machining applications and when working with ultra-hard materials.

This production process exemplifies Tungaloy’s unwavering commitment to innovation, precision, and excellence—reinforcing confidence that every CBN insert delivered meets the highest standards of modern manufacturing and industrial performance.

We then observed the application of Additive Manufacturing : Metal 3D Printing in mass production processes has significantly enhanced efficiency, precision, and design flexibility of cutting tool manufacturing, while maintaining high quality and precision of workpiece in accordance with the standards.

Additive Manufacturing also streamlines the production of the DrillMeister cutting head, reducing what was previously a five-step manufacturing process to a single-stage operation. This not only shortens production lead times and lowers manufacturing costs, but also maintains high standards of quality and dimensional accuracy.

The delegation then proceeded to observe the insert pressing process, which is carried out using high-precision presses. The pressed inserts are subsequently transferred to the sintering process, where the material structure is fully consolidated to achieve the required mechanical properties for cutting applications. Following sintering, the inserts undergo grinding on both the top and bottom surfaces to precisely control thickness and flatness according to stringent micron-level standards. This grinding step is critical to ensuring the quality and consistency of cutting tools in all types of machining operations.

The final stage of the visit was the cutting tool coating process, which utilizes advanced CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition) technologies. These multi-layer coating techniques are engineered to significantly enhance the overall performance of cutting tools. Compared to single-layer coatings, multi-layer structures offer superior distribution and resistance to frictional forces, thereby extending tool life and minimizing the formation of built-up edges. The resulting smooth and uniform surface finish supports stable cutting conditions and contributes to improved workpiece surface quality.

This Plant Tour offered an invaluable and truly inspiring experience, providing participants with a rare opportunity to witness the world-class innovation behind the manufacturing of cutting tools. From the high-precision production of CBN inserts—powered by cutting-edge technology and rigorous quality control—to the impressive application of Additive Manufacturing that elevates both productivity and flexibility, every process showcased Tungaloy’s dedication to excellence. The tour also highlighted the advanced Multi-Layer Coating technology, reflecting the company’s deep expertise and commitment to delivering top-tier performance. Throughout the visit, participants gained not only extensive technical knowledge but also a renewed sense of confidence and inspiration in the future of advanced manufacturing.

Though every celebration must eventually come to an end, the memories from the Asia Dinner Party will remain in our hearts for a long, long time. It was an evening filled with warmth, laughter, and heartfelt connections — a beautiful finale to our journey, made even more special by the presence of Mr. Satoshi Kinoshita, President of Tungaloy Corporation, and the factory team who joined us in celebration with genuine camaraderie.

One of the night’s most unforgettable highlights was the captivating performance of Towa Taiko — traditional Japanese drumming that powerfully embodies the strength and spirit of Japanese culture. The rhythm stirred our emotions, and the excitement soared as we were invited to try our hand at the drums ourselves, creating an experience that was both interactive and deeply memorable. The evening brought more than just joy; it built bridges of friendship and mutual respect that transcend borders. As we part ways, we carry not only souvenirs, but also the lasting impressions of a truly meaningful and inspiring journey — one that will echo in our hearts for years to come.

MEGA Tech is honored to conclude our Episode 2 report of the Tungaloy Dealer Asia Seminar 2025, and we extend our sincere appreciation to all attendees and readers for your continued interest and support.

If you’re seeking a new approach to elevate your production performance — or facing challenges that demand intelligent, high-precision solutions — now is the time to transform every obstacle into an opportunity for lasting success.

Tungaloy – NTK (Thailand) Co., Ltd., together with Thailand’s leading dealer partners, stands ready to support you every step of the way. Backed by world-class cutting tool innovation and deep industry expertise recognized on a global scale, we are the driving force behind the next level of manufacturing excellence — where precision, efficiency, and sustainability come together.

Reach out today and unlock a new dimension of potential that will redefine your production process beyond what you ever imagined.

Follow the article Episode 1 Tungaloy Dearler Seminar 2025 at this link. << Click Here

Article by: MEGA Tech << Click Here