As Thailand’s industry sector is transforming into an efficient and low-carbon operation, adopting high-tech tools and equipment is essential to achieve these objectives. PTSC’s Open House 2025 is therefore organized aiming to provide updates in machining and measurement trends specially tailored for the customers and visitors. With the 3rd edition of this year, PTSC presents form inspection tools from Accretech and cutting tools from Tungaloy. MEGA Tech is proud to present highlights of the event for our readership.

Accretech: RONDCOM NEX Satisfies Various Measurement Needs

When it comes to roundness and roughness, traditional inspection tools not only bring unsure accuracy but are also time-consuming. Designed to eliminate all concerns, the form testers of the RONDCOM NEX series enable precise measurements of roundness and roughness in the R, T and Z axes and feature best-in-class rotational accuracy. The inspection scope extends to cylinder form, perpendicularity, parallelism, straightness, flatness, coaxiality, concentricity, and thickness with rotational error of just 20 nanometers. It’s ideal for a wide range of precision parts with a height of 300 mm or 500 mm and weight up to 60 kg.

The series RONDCOM NEX is also available with a labor-saving option: AFD (Automatic Force adjustment Detector). The AFD which helps reduce operator interventions to achieve higher efficiency in measurement, allows automatic adjustment of measurement direction and force in the software. As such, it is possible to automatically measure the outer and inner diameters of a workpiece.

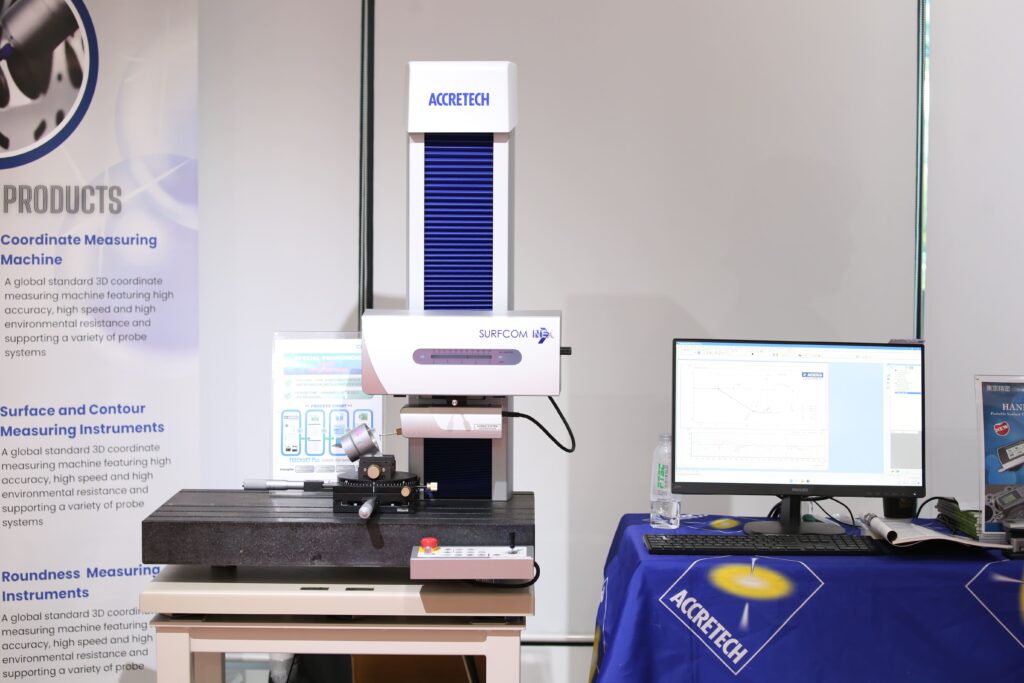

Accretech: Surfcom Nex Surface Texture and Contour Measuring in One Equipment

Whether you want to measure surface texture, contour, or both, the Surfcom Nex from Accretech allows you to get the job done with peace of mind. Equipped with newly developed, wide-range hybrid detectors covering more than twice the range of conventional machines, this machine efficiently evaluates the surface texture and contour of inclined surfaces, undulating shapes, and curved surfaces in one trace.

Preparation and measurement are achieved in a short time thanks to the overwhelming driving speed and wide-range hybrid detectors. SURFCOM NEX inherits the linear motor tracing driver from a conventional SURFCOM NEX. This ultra-low vibration drive mechanism reduces noise caused by vibration and provides high-accuracy measurement results. The temperature sensor built in the linear motor guarantees accuracy for a temperature range of 20°C±5°C in workplaces that’s difficult to control.

Surfcom Nex machine brings efficiency and at the same time reduces cycle time. With a newly developed hybrid detector, both surface texture and contour can be measured in a single trace. A measurement range is 2.6 times as wide as that of conventional instruments. The new column and tracing driver allow for a fast approach to and retraction from the measurement point reducing the total inspection time.

Tungaloy Expands Its DrillMeister Series

Small hole drilling for high-precision parts presents several challenges, such as tool stiffness, chip removal and maintaining precise hole location. Another issue is the utilization of that tool with the automatic lathes. With conventional sleeves, the drill overhang must be readjusted during tool changes. Unfortunately, this adjustment process is difficult due to the limited space inside the machine, leading to poor workability and decreased productivity.

To address these challenges, Tungaloy has expanded its DrillMeister exchangeable-head offering stable performance, long tool life, and significant cost-savings for drilling tool systems. The new AddMeisterDril series is specialized designed for automatic lathes by maintaining consistent overhang length during tool changes ensuring high compatibility and stability. It now covers head-changeable drills from 4.0 mm to 8.4 mm in diameter with 3xD drilling depth and is compatible with TinyMiniTurn sleeves.

Quick-Change Mechanism Enhances Work Efficiency

The anti-pull-out design secures the fixation between the head and body ensuring the most stability during the cutting process. The drill head is preset in a dedicated key for easy and quick fastening to the drill body thus head exchangeable structure enables tool changes in approximately 15 seconds. The new design also features easy replacement even in confined machine interiors, significantly reducing setup time, minimizing production line downtime and improving machine utilization.

Excellent Chip Control and Machining Stability

The new body features a specially shaped internal coolant supply ensuring reliable lubrication and cooling at the cutting point ensuring adequate coolant discharge, which is crucial for deep-hole machining. The twisted flute geometry enables stable chip evacuation, even with ductile materials. The body features a special coolant hole design that ensures sufficient coolant discharge for excellent chip evacuation. Internal coolant outlets on the drill body are optimized for effective chip evacuation, providing drilling stability. Supports drilling depths up to 3xD, meeting a wide range of machining requirements.

Wide Range of Head Variations for Versatile Applications

The expanded series is compatible with a wide variety of DrillMeister and ADDMeisterDrill heads. There are two types of heads are available: the versatile “DMP Head” and the “DMC Head” for high-precision holes. It’s now offering various drilling applications, the optimal head selection available based on workpiece material and geometry, and a standardized tool inventory that helps reduce management costs.

PTSC has successfully showcased the in-trend technologies and conducted training sessions. The active participation and feedback from the attendees were overwhelmingly positive, reflecting their satisfaction with the event and the products on display. This successful event underscores PTSC’s commitment to supporting customers and securing its name as a leader in providing metal-cutting tools and metrology products.

For more information, please visit https://ptsc.co.th/