คำอธิบาย

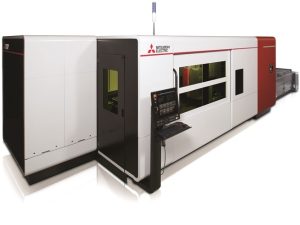

The Phoenix fiber laser combines cost efficiency, dynamic laser cutting, advanced automation solutions and LVD’s intuitive Touch-L control. This all-round system offers fast processing of a wide variety of material types and thicknesses. The machine integrated with the COMPACT TOWER (CT-L) automation system. (CT-L) is material storage and retrieval tower for 4, 6, 8 or 10 pallets. It handles 3050 x 1525 mm sheets with material thicknesses up to 25 mm and has a storage capacity of 3000 kg per shelf. The CT-L unit facilitates lights-out production. The Compact Tower enables automatic loading, unloading and storage of finished parts.

Key automation benefits:

– Maximize productivity and eliminate unproductive time

– Continuous, lights-out manufacturing

– Fully automatic loading and unloading during the production cycle

– Efficient handling of workpieces

– User-friendly, intuitive 19” touch screen control Touch-A

– Highly reliable automated production

– High flexibility to process a variety of material types and thicknesses (CT-L)