Article by: Tungaloy Cutting Tool (Thailand) Co., Ltd.

カティングツールの世界においてチップブレーカーはワークピースのクオリティーを左右する重要な役割を担う部品なのであります。しかしながらかなり多くの人達は殆どと言って良いほどチップブレーカーの重要性に関しての認識または知識がありません。きょうタンガロイは皆様を懇切丁寧に本コンテンツを通してチップブレーカーの幾何学的原理とその性質を説明して皆様のマシンニーズを満たす素晴らしいソリューションを見つけ出す事ができるようにご案内させて頂きます。チップのコントロールに関わる色々な厄介事は軟質な鋼材や超合金の変則的なカットデプスをこなさなければならないターニング操作でのマシンカットフィニッシングやマシンカットセミフィニッシングにおいて共通の問題なのです。

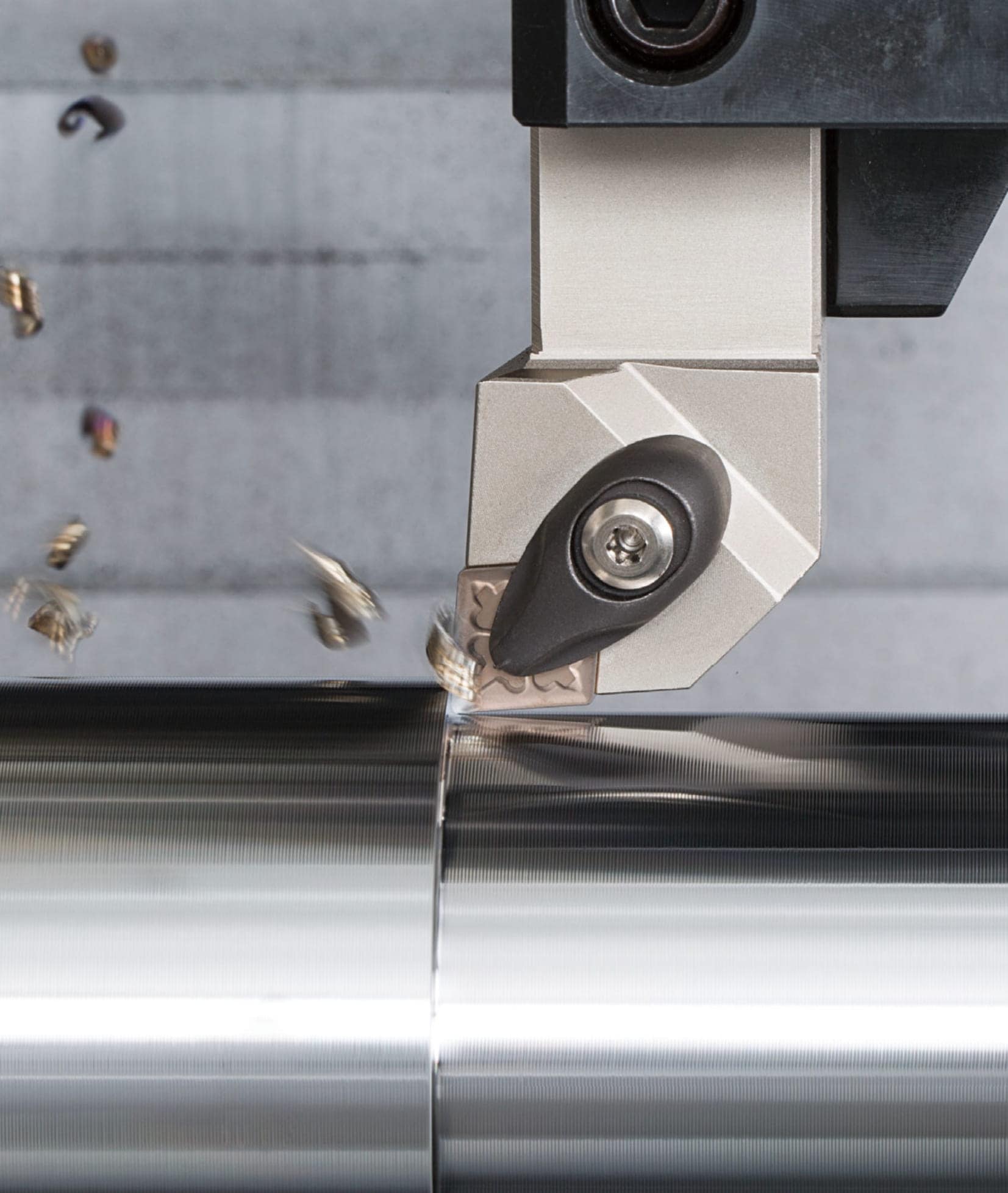

チップのブレーキング処理は実際にはどの様にして起こるのでしょうか?カティングエッジ近くに位置するグルーブタイプのチップブレーカーはチップをカール状に丸めて瞬時に放出します。もしもチップブレーカでチップが適当な長さに切り刻む事ができたならチップがワークピースに纏い付く事は無く振動も減少しツールもそう簡単には破損せずに済みチップブレーカーもカティング時の抵抗を低減させる事ができカティング時の抵抗を低減させれば振動により発生するカティング端の欠けや砕けを防げます。そして更には低減されたカティング抵抗は負荷量と熱を低減させツールの磨耗を遅らせることが出来るのです。

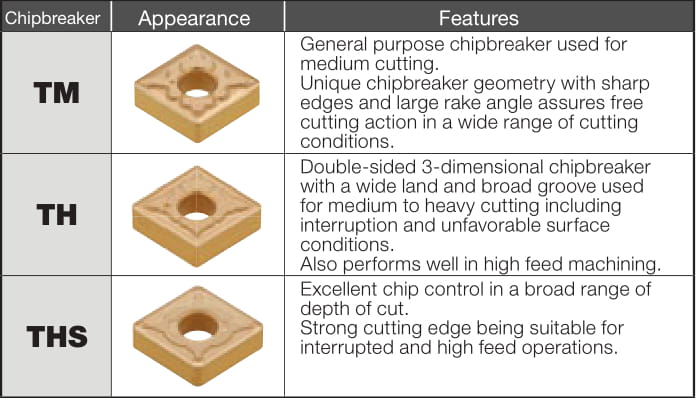

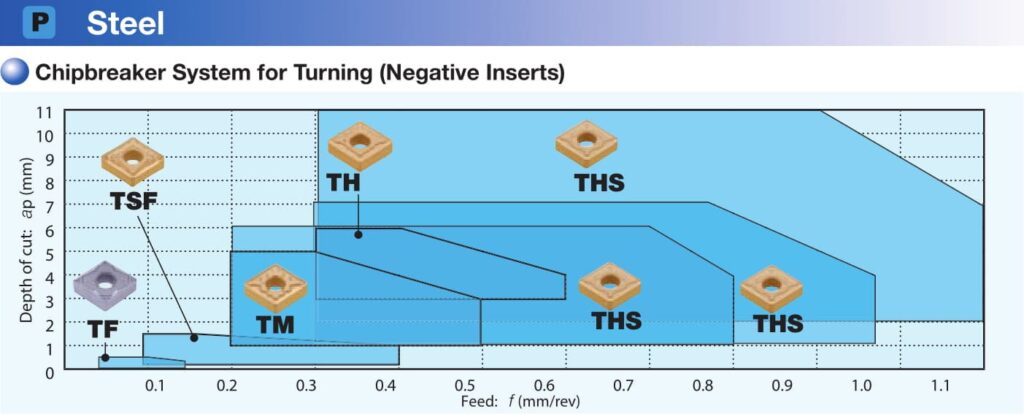

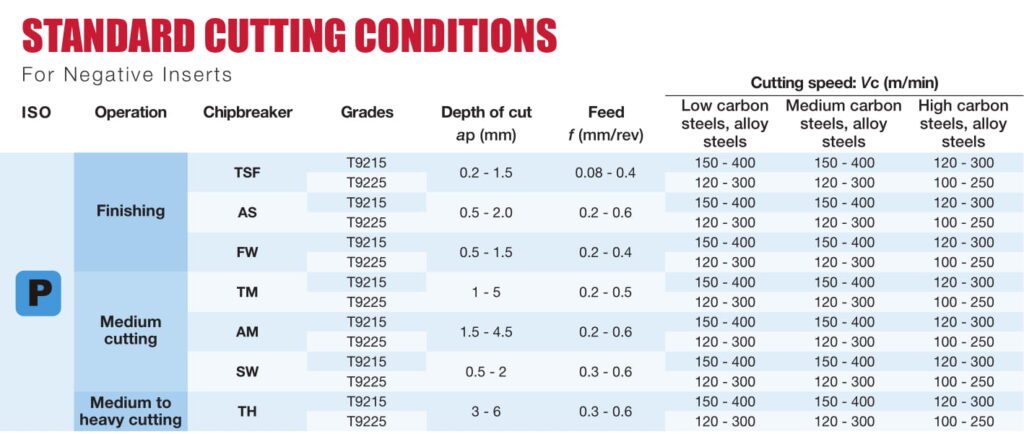

チップブレーカーの選択には幾つか考慮しなければならない点があります。例えば、ワークピースの素材が鉄鋼材なのかステンレス鋼なのか超合金なのか。そしてカティングの条件もその重要な考慮要素の一つです。カティング速度(Vc-m/min)、フィードスピード(f:mm/rev)そしてカットの深さも重要です。そして最後は個々のワークピースも表面のクオリティーによってそれぞれコントロールが必要、例えばラフ面なのかフィニッシュ面なのかも忘れてはいけません。 以上をまとめると、色々なファクター全てがカティング条件を左右するのでチップブレーカー選びにはワークピースの出来上がりおよびにカティングのパフォーマンスの最適化を目的とした賢い、注意深い選択が必要なのです。

個々のタイプのチップブレーカーを見てみると、それらはそれぞれのワークの条件下において違った役割をこなしてます。我々がそれを理解して最適なチップブレーカーを適材適所で選んだのであれば、それでよりカティングのプロセスを改善できそれは時間の節約にも繋がり作業効率を向上させることが出来るのです。しかし何と言ってもここで一番重要なのは皆様のワークピースが正に皆様がオーダーしたそのものである事でしょう。